I’ve seen many coffee brands lose aroma and taste because of wrong packaging. The right bag protects freshness, aroma, and prevents spoilage. Bad packaging kills quality before coffee reaches consumer.

The ideal roasted coffee bag balances air‑barrier performance, strength for weight, and cost — small bags use multilayer film pouches; large weights use laminated woven or reinforced bags.

I’ve helped several roasters design packaging for 250 g to 20 kg bags. I learned that one size never fits all. Below I share how I decide packaging based on bean weight, shelf life, and logistics.

What are packaging material options for different weights of roasted coffee beans?

Choosing material depends on weight, barrier needs and handling. For small bags under 1 kg, thin multilayer films work well. For heavier loads, strong woven or reinforced bags make sense.

Light‑weight coffee needs high‑barrier film. Heavy loads demand strong woven or reinforced bags to avoid tearing and preserve aroma.

Dive Deeper: Material vs weight logic

Why material choice matters by weight

- Small bags (250g–1kg) are handled often. A flexible, glossy film bag makes sense. It seals tight and blocks oxygen.

- Medium bags (2kg–5kg) need stronger layers. Film must resist punctures and hold seal.

- Large bags (10kg–20kg and above) face rough handling and stacking. They need high tensile strength and tear resistance.

Typical material structures by weight

| Bag Weight | Material Structure | Pros | Cons |

|---|---|---|---|

| 250g–1kg | PET / VMPET / PE (multilayer film) | Excellent oxygen barrier; good print | Thin, low mechanical strength |

| 2kg–5kg | PET / MPET / LLDPE (thicker film) | Better strength; barrier maintained | More costly than film for small bags |

| 10kg–20kg | Woven PP outer + laminated film inner | High strength; decent barrier; low cost | Lower printing quality; bulkier |

| 10kg–20kg | Film bag + added nylon layer for puncture resistance | Strong barrier and toughness | Higher cost; heavier bag wall |

I often suggest woven polypropylene (PP) bags with inner laminated film for heavy roasted beans. If clients insist on film bags even at large sizes, I add a nylon layer to boost puncture resistance.

How about the coffee packaging types for different weight?

Bag type often follows bean weight and logistics. For retail and small orders, stand‑up pouches or flat-bottom bags are ideal. For bulk roasting or coffee shops, woven sacks or block-bottom bags suit better.

For light retail packaging, flexible film pouches. For bulk or heavy orders, laminated woven or reinforced block-bottom bags.

Dive Deeper: Types of bags and their uses

- Stand‑up pouches / flat-bottom pouches (250g–1kg): Great for retail shelves and easy reseal. They accept foil or metallized film to lock out oxygen.

- Zip‑lock or valved bags (250g–1kg): Good for ground coffee or beans. Valves let CO₂ escape right after roasting.

- Block‑bottom / gusset bags (1kg–5kg): Durable and space‑efficient, often used for larger retail packs or small wholesale.

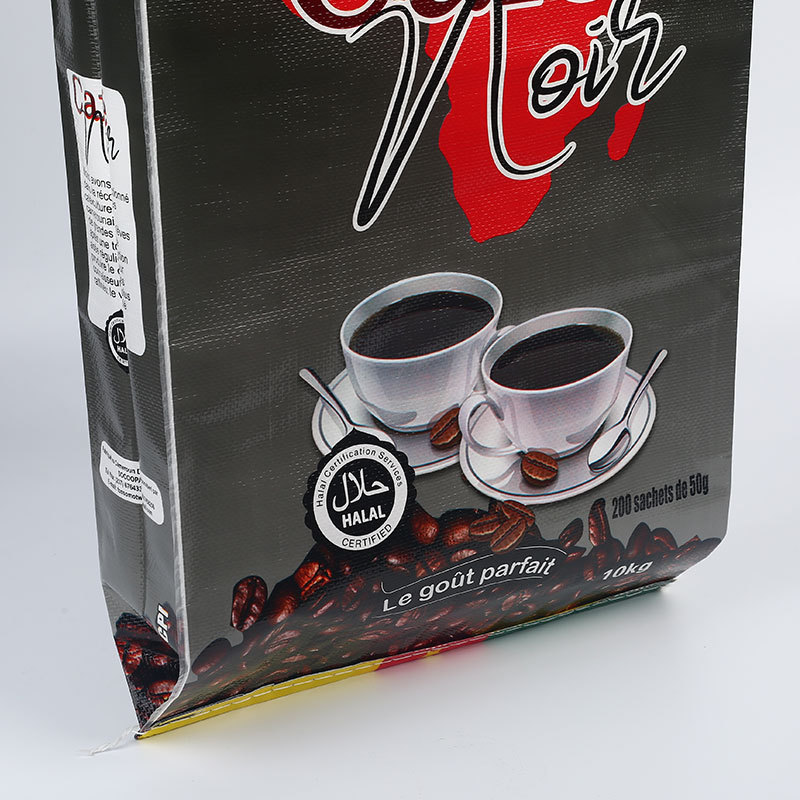

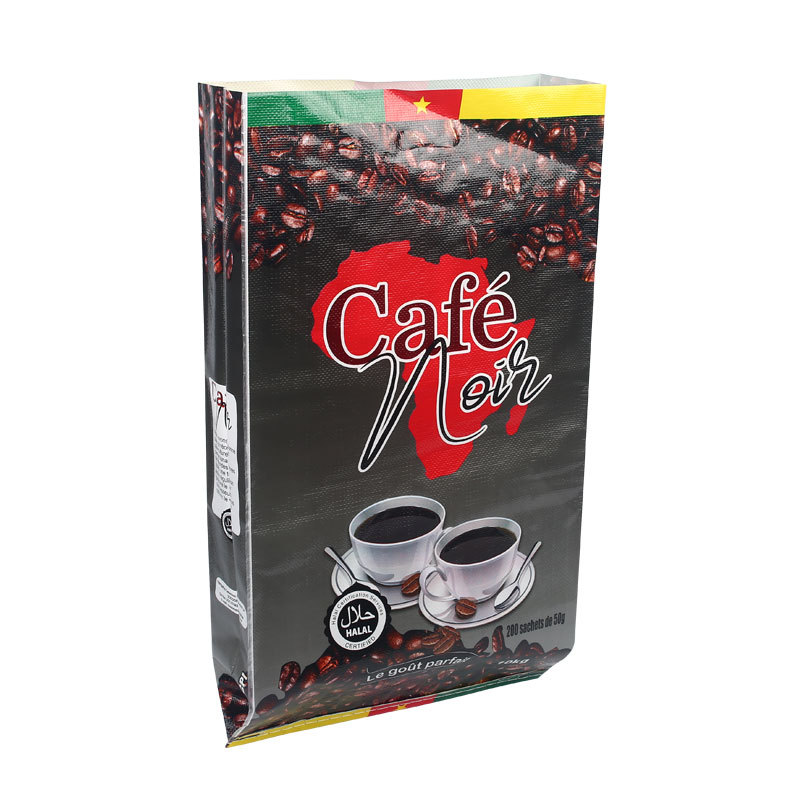

- Laminated woven sacks (5kg–20kg): Rugged and strong. Ideal for wholesale, roasting houses, or transport to cafes.

- Film bags + inner bag liners (bulk): Sometimes used when moisture control is critical. Inner liner keeps barrier; outer layer gives strength.

I usually match the bag type to the buyer’s business model. For direct‑consumer retail I pick pouches. For roasteries supplying cafes, I go for woven sacks or laminated bags.

Commonly used coffee bag sizes

Coffee packaging sizes vary by market and customer type. Smaller sizes go to retail; bigger ones go to cafés or roasters.

Popular bag sizes: 250 g, 500 g, 1 kg for retail; 5 kg, 10 kg, 20 kg for wholesale or bulk buyers.

What’s the ideal packaging bag for roasted coffee beans?

I’ve seen many coffee brands lose aroma and taste because of wrong packaging. The right bag protects freshness, aroma, and prevents spoilage. Bad packaging kills quality before coffee reaches consumer.

The ideal roasted coffee bag1 balances air‑barrier performance, strength for weight, and cost — small bags use multilayer film pouches2; large weights use laminated woven or reinforced bags.

I’ve helped several roasters design packaging for 250 g to 20 kg bags. I learned that one size never fits all. Below I share how I decide packaging based on bean weight, shelf life, and logistics.

What are packaging material options for different weights of roasted coffee beans?

Choosing material depends on weight, barrier needs and handling. For small bags under 1 kg, thin multilayer films work well. For heavier loads, strong woven or reinforced bags make sense.

Light‑weight coffee needs high‑barrier film. Heavy loads demand strong woven or reinforced bags to avoid tearing and preserve aroma.

Dive Deeper: Material vs weight logic

Why material choice matters by weight

- Small bags (250g–1kg) are handled often. A flexible, glossy film bag makes sense. It seals tight and blocks oxygen.

- Medium bags (2kg–5kg) need stronger layers. Film must resist punctures and hold seal.

- Large bags (10kg–20kg and above) face rough handling and stacking. They need high tensile strength and tear resistance.

Typical material structures by weight

| Bag Weight | Material Structure | Pros | Cons |

|---|---|---|---|

| 250g–1kg | PET / VMPET / PE (multilayer film) | Excellent oxygen barrier3; good print | Thin, low mechanical strength |

| 2kg–5kg | PET / MPET / LLDPE (thicker film) | Better strength; barrier maintained | More costly than film for small bags |

| 10kg–20kg | Woven PP outer + laminated film inner | High strength; decent barrier; low cost | Lower printing quality; bulkier |

| 10kg–20kg | Film bag + added nylon layer for puncture resistance4 | Strong barrier and toughness | Higher cost; heavier bag wall |

I often suggest woven polypropylene (PP) bags with inner laminated film for heavy roasted beans. If clients insist on film bags even at large sizes, I add a nylon layer to boost puncture resistance4.

How about the coffee packaging types for different weight?

Bag type often follows bean weight and logistics. For retail and small orders, stand‑up pouches or flat-bottom bags are ideal. For bulk roasting or coffee shops, woven sacks or block-bottom bags5 suit better.

For light retail packaging, flexible film pouches. For bulk or heavy orders, laminated woven or reinforced block-bottom bags5.

Dive Deeper: Types of bags and their uses

- Stand‑up pouches / flat-bottom pouches (250g–1kg): Great for retail shelves and easy reseal. They accept foil or metallized film to lock out oxygen.

- Zip‑lock or valved bags (250g–1kg): Good for ground coffee or beans. Valves let CO₂ escape right after roasting.

- Block‑bottom / gusset bags (1kg–5kg): Durable and space‑efficient, often used for larger retail packs or small wholesale.

- Laminated woven sacks (5kg–20kg): Rugged and strong. Ideal for wholesale, roasting houses, or transport to cafes.

- Film bags + inner bag liners (bulk): Sometimes used when moisture control6 is critical. Inner liner keeps barrier; outer layer gives strength.

I usually match the bag type to the buyer’s business model. For direct‑consumer retail I pick pouches. For roasteries supplying cafes, I go for woven sacks or laminated bags.

Commonly used coffee bag sizes

Coffee packaging sizes vary by market and customer type. Smaller sizes go to retail; bigger ones go to cafés or roasters.

Popular bag sizes: 250 g, 500 g, 1 kg for retail; 5 kg, 10 kg, 20 kg for wholesale or bulk buyers.

Dive Deeper: Market logic behind size choices

- 250 g / 500 g: Perfect for individual consumers. Easy to open, use, and reseal.

- 1 kg: Good for serious home roasters or frequent drinkers.

- 5 kg / 10 kg: Common for cafés or small roasting batches.

- 20 kg: Standard for wholesale supply to coffee shops or distributors. Sometimes 30–50 kg sacks used for transport between countries.

Size choice affects bag strength, bag material cost, storage, and shipping cost. I often walk new clients through these trade‑offs.

Woven Bag or laminated film bag — advantages and disadvantages for roasted coffee beans

Each bag type has trade‑offs. The right choice depends on your priority: barrier, cost, strength, or branding.

Laminated film bags give best aroma barrier and print quality for small retail packages. Woven bags offer strength and low cost for bulk packaging but sacrifice barrier and aesthetics.

Dive Deeper: Pros and cons

| Bag Type | Advantages | Disadvantages |

|---|---|---|

| Laminated film bag | High oxygen/moisture barrier; good sealing; great print quality for branding. | Lower mechanical strength; poor for heavy loads; higher cost at large size. |

| Woven PP laminated bag | Strong, tear‑resistant; handles heavy weight; low cost per kg. | Poor barrier performance; less attractive for retail; printing quality is poor; risk of oxidation over time. |

| Woven bag + inner barrier liner | Combines strength and barrier; good for bulk roasted beans. | More complex production; higher cost than plain woven; bulkier packaging. |

In my work, I rarely recommend plain woven bags for roasted coffee destined for retail. If barrier is critical — as for roasted beans — I insist on laminated film or woven‑with‑liner.

What is the coffee packaging process?

Proper packaging means more than just filling beans into bags. The process affects final quality and shelf life.

A good packaging process includes roasting, resting, degassing (if needed), filling in oxygen‑free environment, sealing, labeling, and storage.

Dive Deeper: Typical steps I follow

- Roast and cool — After roasting, cool beans quickly to stop residual heat.

- Rest or degas — Some beans release CO₂. Wait until degassing slows before sealing.

- Prepare packaging — Choose correct bag type and inspect for defects.

- Fill in low‑oxygen environment — Use nitrogen flush or vacuum sealing if possible.

- Seal properly — Seal seams tightly. For pouches, use heat‑seal. For woven bags, use stitching or heat‑seal liner.

- Label and date — Include roast date, origin, weight, lot number.

- Store correctly — Keep away from heat, light, moisture. Use pallets and dry space.

I always advise clients: don’t skip degassing or nitrogen flush. It makes a big difference in shelf life and flavor preservation.

How to design coffee packaging?

Design is not only about aesthetics. It is also about function and brand perception. Good design helps the product sell — and keeps beans fresh.

Design must balance barrier performance, bag strength, user convenience, and brand image.

Dive Deeper: What I consider when I design packaging

- Material layers — Choose barrier films for roasted beans.

- Bag type & weight — Match bag style to size and usage.

- Seal type — Use resealable zippers for retail; strong seals or liners for bulk.

- Printing & branding — Film bags allow high‑quality printing. Woven bags need special inks or labels.

- User experience — Easy to open, reseal, carry. Add degassing valve if possible.

- Cost control — Keep material and manufacturing cost reasonable while ensuring barrier and strength.

I often prototype 2–3 versions for a client: pouches for retail, and block‑bottom or woven‑liner sacks for wholesale. Then I test them for seal strength, aroma retention, and handling stress.

What are coffee packaging requirements?

Good packaging must meet several requirements. Especially for roasted coffee beans that need oxygen protection and aroma preservation.

Packaging must provide: oxygen barrier, moisture protection, seal integrity, light exclusion, durability, and convenience.

Dive Deeper: Key requirements and why they matter

- Oxygen barrier: Roasted beans oxidize quickly. Oxygen causes stale flavor.

- Moisture barrier: Moisture ruins roast profile and aroma.

- Seal integrity: A weak seal allows air ingress over time.

- Mechanical strength: Bags must survive packing, transport, stacking. Large bags must resist tearing and puncture.

- Barrier against light and odors: Light and external odors affect bean flavor. Opaque materials work best.

- User convenience: Easy to open, reseal, or pour, especially for retail packs.

When discussing with clients, I insist: “If you skip barrier or seal, you lose aroma. If you skip strength, you lose beans.” Packaging is a protective shell — not decoration.

What about commercial coffee packaging?

Commercial clients (roasters, distributors, cafés) often order large volumes. They need cost‑effective, strong packaging that maintains bean quality during transport and storage.

For commercial packaging I favor laminated woven sacks with inner barrier layers or heavy‑duty film bags with added nylon layer. Both balance cost, strength, and barrier.

Dive Deeper: What commercial packaging demands

- Bulk size: 5 kg to 20 kg bags to reduce packing time and cost.

- Durability: Bags stackable, resist wear and tear during loading, transport, and storage.

- Barrier + durability combo: Why a laminated inner layer is important — thick film keeps beans fresh; woven outer layer supports load.

- Cost efficiency: Woven sacks cost less per kg of beans than film pouches. Woven‑liner bags offer good value proportion.

- Ease of handling: Must have handles, standard size for pallets, easy to carry.

In one case, a roaster asked for 25 kg bags. I designed heavy‑duty laminated woven sacks with nylon liner. They passed stacking tests and kept beans fresh for 3 months in warehouse before shipping to cafés.

What about coffee grinding?

Grinding changes the game. Once you grind coffee, exposure to oxygen is massive. Packaging must be even more protective.

If you sell ground coffee, packaging must offer top‑level barrier and reseal capability. Aroma and flavor fade fast.

Dive Deeper: Grinding affects packaging needs

- Surface area increases: Ground coffee oxidizes faster than whole beans.

- Need resealable bags: Consumers often use ground coffee over several days. A zipper or resealable closure helps.

- Barrier must remain high: No simple paper bags. Must use foil‑based multilayer films with oxygen and moisture barrier.

- Small portion packaging: Ground coffee often sold in 250 g–500 g. That size must balance barrier, seal strength, and shelf appeal.

I recommend clients treat ground coffee like roasted beans — but with stricter requirements. I pick PET/AL/PE pouches with resealable zippers for ground packages. For bulk ground supply, I still use heavy barrier film bags but with inner liner and strong outer layer.

Conclusion

Choosing right ruined packaging kills quality. Good packaging preserves aroma and taste.

For roasted coffee, barrier and strength matter most. Match bag type and material to bean weight and use.

For retail: multilayer film pouches. For bulk: laminated woven or reinforced bags. For ground coffee: sealed high‑barrier pouches.

That is how I help coffee brands protect quality and value.

-

Explore this link to understand how the right bag can preserve the aroma and taste of your coffee. ↩

-

Learn about the benefits of multilayer film pouches for small coffee bags and their role in maintaining freshness. ↩

-

Find out how oxygen barriers protect coffee from spoilage and maintain flavor. ↩

-

Understand the importance of puncture resistance in coffee bags, especially for heavy loads. ↩ ↩

-

Explore the advantages of block-bottom bags for larger retail packs and their space efficiency. ↩ ↩

-

Learn about the importance of moisture control in coffee packaging and how it affects quality. ↩