Want to make your packaging stand out on the shelf but not sure how?

Spot UV1 and foil stamping2 are two popular finishes that can enhance the look, texture, and impact of your flexible packaging bags3.

I used to think packaging was just about function. Then I learned how finishes like Spot UV1 and foil could completely change how customers see your brand.

What is the difference between spot UV and foil stamping2?

They both shine, but not in the same way.

Spot UV1 adds clear gloss to specific areas of the bag, while foil stamping2 uses metallic foil4 pressed with heat for a reflective, premium look.

Dive Deeper: Technique, texture, and use cases

Application methods

- Spot UV1 uses a liquid varnish applied to targeted areas, then cured under ultraviolet light. It creates raised, shiny highlights.

- Foil stamping applies colored or metallic foil4 using heat and pressure. It’s ideal for metallic logos, borders, or patterns.

Visual impact

| Feature | Spot UV1 | Foil Stamping |

|---|---|---|

| Look | Glossy and clear | Metallic, shiny |

| Texture | Smooth, slightly raised | Crisp, bold, tactile |

| Detail level | Fine lines and patterns | Best with simple, bold elements |

Cost and production

- Spot UV1 doesn’t require a die, so it’s more affordable for short runs.

- Foil stamping needs a custom metal plate, increasing cost but adding prestige.

What is spot UV on packaging?

I used to wonder—what’s that shiny texture on just one part of the bag?

Spot UV1 is a high-gloss coating5 applied to specific parts of the packaging to highlight elements like logos or patterns.

Dive Deeper: Where and why to use spot UV

Best uses for spot UV

- Over matte-laminated backgrounds6, spot UV creates sharp contrast.

- It works well for highlighting brand logos, product names, or illustrations.

- Especially effective on kraft paper or soft-touch finishes.

Functional benefits

- It adds scratch resistance7 to selected areas.

- It also gives the bag a “premium” feel at a lower cost than foil.

- On retail shelves, it catches light and draws eyes toward key design elements.

Materials compatible with spot UV

| Substrate | Spot UV1 Compatibility |

|---|---|

| Matte laminated BOPP | ✅ Excellent |

| PET film | ✅ Good |

| Kraft paper | ✅ Ideal |

| Gloss film | ❌ Less contrast |

What is the difference between UV and foil?

I used to mix them up—glossy is glossy, right? Turns out, they’re quite different.

UV is a clear varnish coating, while foil stamping2 is a metallic film. One uses light, the other uses heat and pressure.

Dive Deeper: Design, durability, and choice

Durability

- Spot UV1 can scratch under rough handling but holds up for retail.

- Foil is more durable for high-touch packaging like zipper bags.

Aesthetic tone

Production factors

| Factor | Spot UV1 | Foil Stamping |

|---|---|---|

| Setup cost | Low | High (die required) |

| Lead time | Fast | Slower |

| MOQ requirement | Lower | Higher |

| Eco impact | Less waste | Foil scraps created |

What is UV printing8 in packaging?

I often hear “UV print” thrown around, but what does it mean?

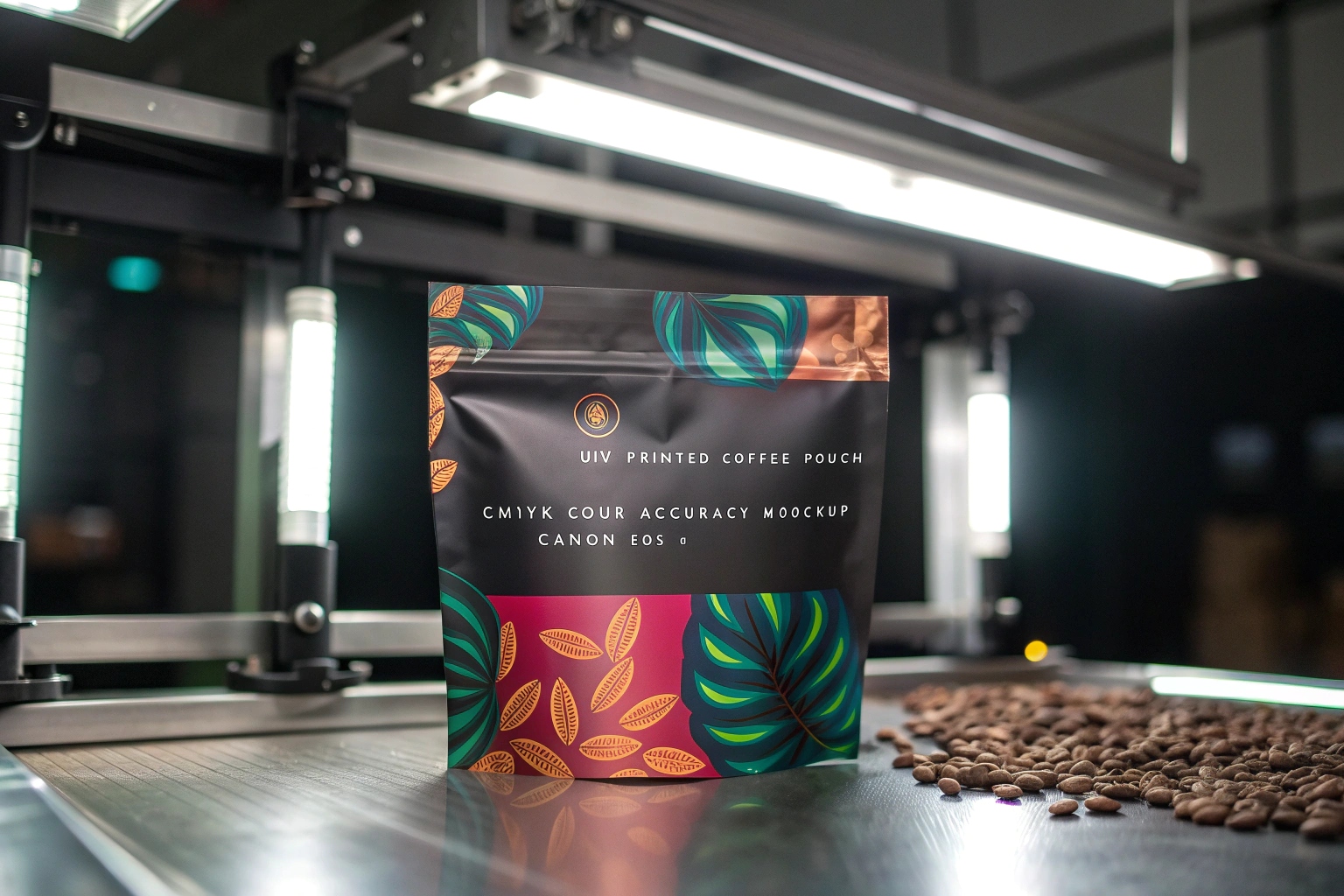

UV printing8 uses ultraviolet light to instantly cure ink on the surface, producing vivid colors and sharp designs, especially on flexible materials.

Dive Deeper: How UV printing8 works in real packaging

Advantages of UV printing8

- Instant drying means faster production and fewer smudges.

- Works on non-porous films like PET, BOPP, and metallic laminates.

- Produces crisp, high-contrast designs that look sharp and professional.

Why combine with spot UV or foil?

- Use UV printing8 for the full-color base design.

- Add spot UV for shine and tactile feel.

- Add foil for metallic impact and brand prestige.

Things to consider

- UV printing8 may cost more than conventional methods, but it enables shorter runs with better color vibrancy.

- It’s ideal for brands looking to produce premium pouches without long lead times.

Conclusion

Spot UV1 and foil stamping2 are both powerful ways to elevate flexible packaging.

Spot UV1 gives a clean, glossy finish to selected areas, while foil stamping2 delivers metallic shine and luxury appeal.

UV printing8, meanwhile, allows for sharp, fast, vibrant color printing on flexible materials.

I’ve used both in different projects. When I want a modern feel, I go with Spot UV1. For high-end coffee lines or gift sets, foil always wins. It’s not just about looks—it’s about experience.

-

Explore how Spot UV can elevate your packaging design with its glossy finish and targeted highlights. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Discover the luxurious appeal of foil stamping and how it can make your packaging stand out. ↩ ↩ ↩ ↩ ↩ ↩

-

Learn about flexible packaging bags and why they are a popular choice for modern brands. ↩

-

Learn about the use of metallic foil in packaging and its impact on brand perception. ↩ ↩

-

Find out how high-gloss coatings can enhance the visual appeal of your packaging. ↩

-

Understand the contrast created by matte-laminated backgrounds and Spot UV for effective branding. ↩

-

Explore the importance of scratch resistance in packaging and how it affects product longevity. ↩

-

Discover the advantages of UV printing for vibrant and sharp designs on flexible materials. ↩ ↩ ↩ ↩ ↩ ↩ ↩