Custom printed stand up bag

Stand-up bag is a versatile and effective packaging solution that offers numerous benefits for both consumers and manufacturers. Its popularity is expected to continue to grow as more businesses recognize the advantages of this type of packaging for their products.

Additional information

| color | custom |

|---|---|

| size | custom |

| description | custom printed stand up bag |

| valve | no degassing valve |

| stock | NO |

Product details

Stand-up bag, also known as a stand-up pouch or a doypack, is a flexible packaging solution that has become increasingly popular in recent years. It is a type of pouch that is designed to stand upright on a shelf or display, making it easy to store and display products.

The stand-up bag is made of multiple layers of flexible materials, which can include plastic, aluminum foil, and paper. These materials are laminated together to create a strong and durable package that can protect the contents from moisture, oxygen, and other environmental factors that could cause spoilage or degradation.

The design of the stand-up bag includes a gusseted bottom, which allows the bag to expand and stand upright. It also typically includes a resealable zipper or other type of closure, which allows the consumer to open and close the bag multiple times without compromising the freshness or quality of the contents.

Stand-up bags are used for a wide range of products, including food, beverages, pet food, cosmetics, and household products. They offer several advantages over other types of packaging, including:

- Convenience: The stand-up bag is easy to store and transport, and its upright design makes it easy to display on a shelf or countertop.

- Protection: The multiple layers of materials used in the stand-up bag provide excellent protection against moisture, oxygen, and other environmental factors that could affect the quality of the contents.

- Sustainability: Stand-up bags are often made from lightweight and recyclable materials, which can reduce the environmental impact of packaging waste.

- Branding: Stand-up bags can be customized with high-quality graphics and branding, which can help to increase brand recognition and appeal to consumers.

Overall, the stand-up bag is a versatile and effective packaging solution that offers numerous benefits for both consumers and manufacturers. Its popularity is expected to continue to grow as more businesses recognize the advantages of this type of packaging for their products.

Here are some of the most commonly asked questions on stand-up bags:

- What is a stand-up bag? A stand-up bag is a type of flexible packaging that is designed to stand upright on its own when filled with product. It typically has a flat bottom gusset that allows it to stand up.

- What are stand-up bags made of? Stand-up bags can be made of various materials, including plastic (such as polyethylene and polypropylene), paper, and foil laminates. The material used depends on the product being packaged and the desired level of protection.

- What products are commonly packaged in stand-up bags? Stand-up bags are commonly used for packaging dry food products such as snacks, coffee, pet food, and powders. They can also be used for non-food products like laundry detergent, pet litter, and garden seeds.

- What are the benefits of using stand-up bags? Stand-up bags offer several benefits, including easy storage and transportation, extended shelf life for the packaged product, and excellent protection from moisture, oxygen, and other external factors that can affect product quality.

- Can stand-up bags be customized? Yes, stand-up bags can be customized to suit specific product requirements. Customization options include size, shape, color, and printing design.

Are stand-up bags recyclable? It depends on the material used to make the stand-up bag. Some materials like polyethylene are recyclable, while others like foil laminates are not easily recyclable. Consumers should check with their local recycling program for information on how to properly dispose of stand-up bags.

How to make stand up packaging bag?

To make a stand-up packaging bag, you will need the following materials and equipment:

Materials:

- Packaging film (plastic or paper-based)

- Zipper or resealable closure (optional)

- Labels or stickers (optional)

Equipment:

- Bag making machine

- Heat sealer

- Scissors or a cutting tool

- Printer (optional)

Here are the steps to make a stand-up packaging bag:

- Choose the appropriate packaging material film for your product. The film should be sturdy enough to hold the weight of the product and provide a barrier to moisture, oxygen, and light.

- Design your bag by considering the size, shape, and branding. You can use a bag template or create your design from scratch. Include any necessary information such as product name, weight, ingredients, and nutritional information.

- Use a bag making machine to create the bag. The machine will form the film into the desired shape and size. Follow the manufacturer's instructions to operate the machine properly.

- Use a heat sealer to seal the edges of the bag. This will prevent any leaks or spills from occurring. Make sure the seal is strong and airtight.

- If you want to include a zipper or resealable closure, attach it to the bag using the heat sealer.

- Cut off any excess film from the edges of the bag using scissors or a cutting tool.

- If desired, print labels or stickers to add branding or additional information to the bag. Attach them to the bag using the heat sealer.

- Your stand-up packaging bag is now ready to use! Fill it with your product and display it on store shelves or ship it to customers.

Note: It's important to follow all applicable regulations and guidelines when designing and producing packaging for your product.

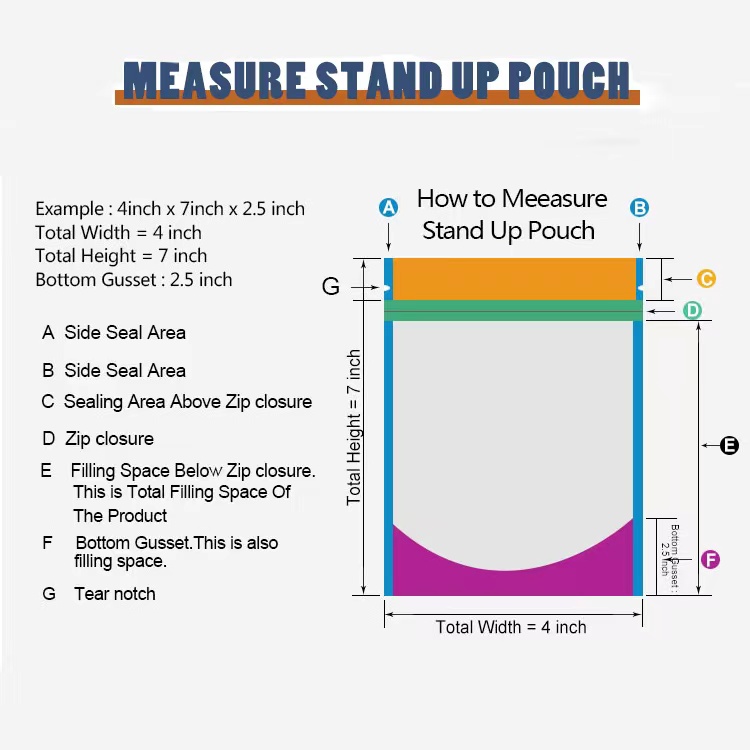

How to measure stand up bag?

To measure a stand-up bag, you will need a ruler or tape measure.

- Start by measuring the width of the bag, which is the distance across the front of the bag from one side to the other.

- Next, measure the depth of the bag, which is the distance from the front of the bag to the back.

- Finally, measure the height of the bag, which is the distance from the bottom of the bag to the top, excluding the portion of the bag that folds over to create the seal.

When measuring the bag, be sure to measure accurately and include any bulges or contours in your measurements. Also, make sure to measure the bag when it is filled or expanded, as this will give you a more accurate measurement.

What industry are the stand up bag commonly used in?

Stand-up bags are commonly used in the food and beverage industry, particularly for packaging products such as coffee, tea, snacks, pet food, and liquid beverages. They are also used in the pharmaceutical industry for packaging of drugs and supplements. Stand-up bags are preferred because they provide better protection against moisture and air, are convenient to use, and are available in a variety of sizes and styles. Additionally, stand-up bags can be customized with branding and design, making them a popular choice for businesses looking to promote their products.

What features can i add on the stand up bag?

Stand up bags are versatile packaging solutions that offer a range of features to meet the needs of various products and industries. Some features that you could consider adding to your stand up bag include:

- Zipper closure: A zipper closure allows for easy opening and closing of the bag, making it a convenient option for consumers.

- Tear notch: A tear notch makes it easy for consumers to tear open the bag without the need for scissors or other tools.

- Hang hole: A hang hole allows the bag to be hung on a hook or display rack, making it easy to merchandise and display.

- Degassing valve: A degassing valve allows for the release of air or gas from the bag, which is useful for products that release gas or require air circulation.

- Window: A window provides a view of the contents inside the bag, which can be an effective way to showcase the product and attract consumers.

- Matte or gloss finish: Matte or gloss finishes can be applied to the bag to provide a more premium look and feel.

- Resealable closure: A resealable closure allows consumers to reseal the bag after opening, keeping the contents fresh and secure.

- Spout or nozzle: A spout or nozzle allows for controlled dispensing of liquids or semi-solid products, making it a popular option for food and beverage products.

- Handle: A handle can be added to the bag to make it easy to carry, which is useful for larger bags or products that are frequently transported.

- Tin tie: A tin tie can be added to make the bag easy to oepn and close, which is very conveniently used.

These are just a few examples of features that you could add to your stand up bag. The specific features you choose will depend on the needs of your product and target market.