Custom printed flat bottom bag

Flat bottom bags are a popular type of packaging that offers several advantages over other types of packaging, including stability, improved branding, increased shelf life.

Additional information

| color | custom |

|---|---|

| size | custom |

| description | Flat bottom bag used for coffee beans, or coffee power packaging |

| valve | Can be added when requested |

| stock | NO |

Product details

Flat bottom bag, also known as a block bottom bag or a square bottom bag, is a type of packaging that has become increasingly popular in recent years. This type of bag is characterized by its flat bottom and square shape, which provides stability and allows it to stand upright on its own. Flat bottom bags are commonly used in the food, pet food, and non-food industries for packaging a variety of products, including coffee, tea, nuts, snacks, grains, and more. In this article, we will explore the characteristics, advantages, and uses of flat bottom bags.

Characteristics of Flat Bottom Bags?

Flat bottom bags are made of laminated materials that offer durability, puncture resistance, and barrier protection. The most common materials used in the construction of flat bottom bags are plastic films such as PET, PE, BOPP, and aluminum foil, which are often combined to create a multilayer structure that offers superior protection against moisture, oxygen, and other external factors that can compromise the quality of the product inside. In addition, the laminated structure of flat bottom bags allows for high-quality printing and graphic design, which can enhance the visual appeal and branding of the product.

The flat bottom of the bag is achieved through a process called block bottoming, which involves folding the film to create a flat base and then sealing the sides to form a four-corner seal. The result is a bag with a stable base that can stand upright on its own, even when it is empty. Flat bottom bags can be produced in a variety of sizes and shapes, with or without a zipper, and can be customized with a range of features such as tear notches, hang holes, and degassing valves.

Advantages of Flat Bottom Bags?

Flat bottom bags offer several advantages over other types of packaging, including:

- Stability: The flat bottom of the bag provides a stable base that allows it to stand upright on its own, which makes it easier to fill and display on store shelves.

- Improved Branding: The large surface area of flat bottom bags allows for high-quality printing and graphic design, which can enhance the visual appeal and branding of the product.

- Increased Shelf Life: The laminated structure of flat bottom bags provides superior barrier protection against moisture, oxygen, and other external factors that can compromise the quality of the product inside, which can extend the shelf life of the product.

- Convenient and User-Friendly: Flat bottom bags are easy to open and close, and can be equipped with features such as zippers and tear notches that make them more user-friendly.

- Eco-Friendly: Flat bottom bags can be made of recyclable materials, which makes them an eco-friendly option for packaging.

Uses of Flat Bottom Bags?

Flat bottom bags are used in a wide range of industries for packaging various products, including:

- Food Industry: Flat bottom bags are commonly used for packaging coffee, tea, nuts, snacks, grains, and other food products. The barrier protection provided by the laminated structure of the bags helps to preserve the freshness and quality of the products inside.

- Pet Food Industry: Flat bottom bags are also used for packaging pet food, such as dog and cat food. The bags can be made of durable materials that are resistant to punctures and tears, which helps to prevent spills and leaks.

Non-Food Industry: Flat bottom bags are also used in the non-food industry for packaging products such as detergents, fertilizers, and other household items. The bags can be customized with features such as hang holes and degassing valves to suit the specific needs of the product.

Commonly asked questions about flat bottom coffee bag?

- What is a flat bottom coffee bag? A flat bottom coffee bag is a type of packaging that is designed to store and transport coffee beans or ground coffee. It is characterized by its unique flat bottom, which allows it to stand upright on a shelf or display.

- What materials are used to make flat bottom coffee bags? Flat bottom coffee bags are typically made of laminated materials such as plastic, aluminum, and paper. These materials are chosen for their ability to protect the coffee from moisture, light, and air.

- What are the advantages of using flat bottom coffee bags? Flat bottom coffee bags have several advantages over traditional coffee bags, including better protection against moisture, light, and air, which helps to maintain the flavor and aroma of the coffee. They are also more stable and easier to stack and display on shelves.

- Are flat bottom coffee bags recyclable? Many flat bottom coffee bags are made from materials that can be recycled, including paper and some types of plastic. However, the recyclability of these bags depends on the specific materials used and the recycling programs available in your area.

- Can flat bottom coffee bags be used for other products? Yes, flat bottom bags can be used to package a variety of other products, including snacks, nuts, and other dry goods. The flat bottom design provides stability and makes the bag easier.

- What sizes are available for flat bottom coffee bags? Flat bottom coffee bags come in a range of sizes to suit different coffee quantities and packaging requirements. Common sizes include 250g, 500g, and 1kg bags.

- Can flat bottom coffee bags be customized? Yes, flat bottom coffee bags can be customized with a variety of design elements, including colors, graphics, logos, and text. This allows coffee brands to create unique packaging that helps them stand out on store shelves and build brand recognition among consumers.

- Are flat bottom coffee bags environmentally friendly? Flat bottom coffee bags can be environmentally friendly, depending on the materials used to make them. Some manufacturers offer flat bottom coffee bags made from compostable materials, such as plant-based plastics or paper. Additionally, some brands may use recyclable or biodegradable materials in their packaging. It is important to check the packaging details to determine the level of eco-friendliness of each product.

- Are flat bottom coffee bags suitable for use with coffee pods? No, flat bottom coffee bags are not suitable for use with coffee pods. Coffee pods require specialized packaging that is designed to accommodate the shape and size of the pods, while also protecting them from external elements.

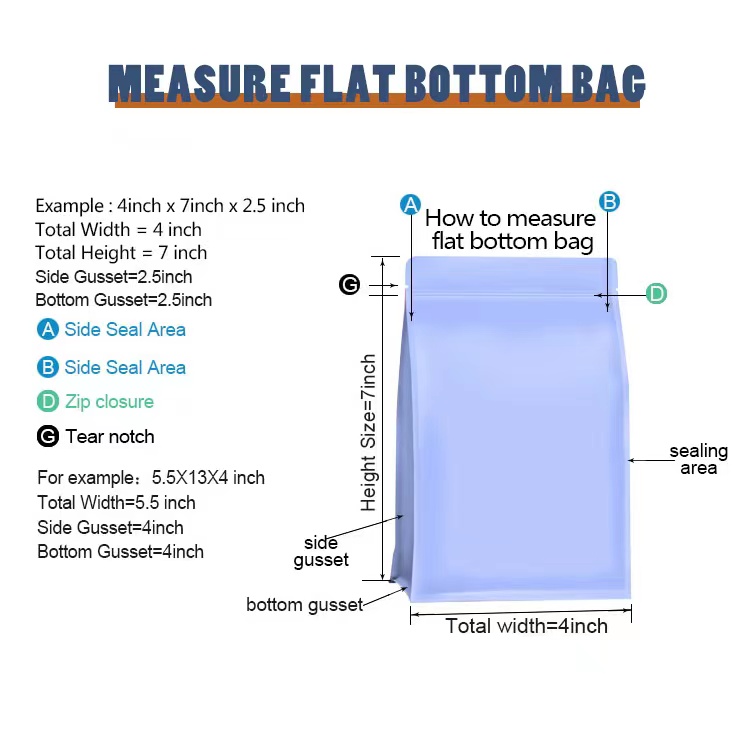

How to measure the square bottom bag?

To measure a square bottom bag, you will need to measure both the width and the depth of the bag.

Here are the steps to measure a square bottom bag:

- Lay the bag flat on a table or other flat surface.

- Measure the width of the bag by placing the measuring tape across the widest part of the bag. This will give you the measurement of the bag from left to right.

- Measure the depth of the bag by placing the measuring tape at the bottom of the bag, in the middle of one side, and then pulling it straight up to the top of the bag. This will give you the measurement of the bag from top to bottom.

- Record both measurements, and if you need to find the square footage of the bottom of the bag, simply multiply the width measurement by the depth measurement.

If the bag has gussets (triangular panels on the sides of the bag), you will need to measure the width and depth of each panel and add those measurements to the width and depth of the bag to get an accurate total measurement.

In conclusion, flat bottom bags are a popular type of packaging that offers several advantages over other types of packaging, including stability, improved branding, increased shelf life.