I’ve seen dried fruits spoil long before reaching customers. Often the fruit is fine—the problem is weak packaging. This is more common than people think, especially when storing products for more than a few months.

Moisture-proof1 and oxygen barrier materials are essential for dried fruit packaging. Use transparent film for under 6 months, metallized film for 12–24 months, and pure aluminum foil for 24 months or longer.

Let’s explore what materials work best, what shelf life you can expect, and how packaging impacts dried fruit quality and sales.

What is the best packing material for dry fruit?

The best packing material for dried fruits combines moisture resistance, oxygen barrier, and light protection. Metallized films2 or aluminum foil are ideal for long-term storage. Clear films suit short-term needs.

Why barrier matters

Moisture makes fruits sticky. Oxygen breaks down oils and vitamins. Light fades the product and encourages spoilage. If the barrier fails, shelf life drops fast—even if the fruit quality is high.

Material types comparison

| Material | Moisture Barrier | Oxygen Barrier3 | Light Barrier | See-through | Suitable Shelf Life4 |

|---|---|---|---|---|---|

| Transparent PET/PE | Medium | Medium | Low | Yes | 0–6 months |

| Metallized PET/PE | High | High | Medium | Partial | 6–24 months |

| Aluminum Foil5 | Very High | Very High | Very High | No | 12–48 months |

I often suggest adding a small clear window to aluminum foil or metallized bags, so customers can see the fruit while still keeping full protection.

Application tip

If your dried fruit will sell fast—under 6 months—a clear bag works fine. For longer sales cycles, invest in metallized or foil materials to keep quality intact.

What is the shelf life of packed dried fruits?

With the right packaging and storage, dried fruits can last from 6 to 48 months. Shelf life depends on packaging material and environmental conditions.

Shelf life by material

| Packaging Material6 | Shelf Life4 Range |

|---|---|

| Transparent Laminate | 3–6 months |

| Metallized Laminate | 12–24 months |

| Aluminum Foil5 Bag | 24–48 months |

If your storage has stable temperature and low humidity, the fruit lasts even longer.

What reduces shelf life

- Humidity7: Causes stickiness and mold

- Oxygen: Oxidizes oils, fades flavor

- Light: Breaks down color and nutrients

- Bad sealing: Allows air and moisture inside

Storage advice

Keep dried fruits in a cool, dry, dark place—always. Even the best material can’t help if the bags sit under the sun or next to a heat vent.

What are the specifications of dried fruits needed?

Dried fruits vary by shape, moisture, and oil content. These affect which packaging material works best and what barrier level is required.

Typical moisture and oil content

| Fruit Type | Moisture Content | Oil Sensitivity |

|---|---|---|

| Raisins | 15–18% | Low |

| Dried Mango | 12–15% | Medium |

| Dried Apricot | 18–20% | Low |

| Dried Banana | 10–12% | Medium |

| Dried Figs / Dates | ~15% | High |

Higher moisture or oil levels need better oxygen and moisture barriers.

Packaging spec recommendations

- For oily fruits: Use metallized or foil film

- For sticky textures: Use high-barrier inner film like PE/CPP to avoid adhesion

- For large chunks: Use thicker laminate to avoid punctures

What are the packaging requirements for dry goods?

Packaging for dried fruits must prevent moisture, oxygen, and light exposure. It must also support hanging display, resealing, and retail visibility.

Key performance needs

Moisture-proof1ing

This is most critical. Moisture turns dry fruit sticky and shortens life. Use barrier films with low WVTR (Water Vapor Transmission Rate8).

Oxygen protection

Oxidation damages flavor and oil content. Good films have low OTR (Oxygen Transmission Rate9).

Light blocking

Sunlight and strong lighting affect color and vitamins. Metallized and foil layers prevent this. Use a small window if necessary.

Sealing and reseal10

Seal must be tight to block air. A zipper allows consumers to reseal after opening.

Retail features

- Euro slot / round hole: For hanging on pegs

- Clear window: To show the fruit without compromising protection

- Tear notch: Easy to open

- Stand-up pouch / 8-side seal: For shelf display

Material testing

| Test | Ideal Value |

|---|---|

| WVTR | <1.0 g/m²/day |

| OTR | <10 cc/m²/day |

These ensure the bag resists water vapor and air.

What are 5 materials used in food packaging?

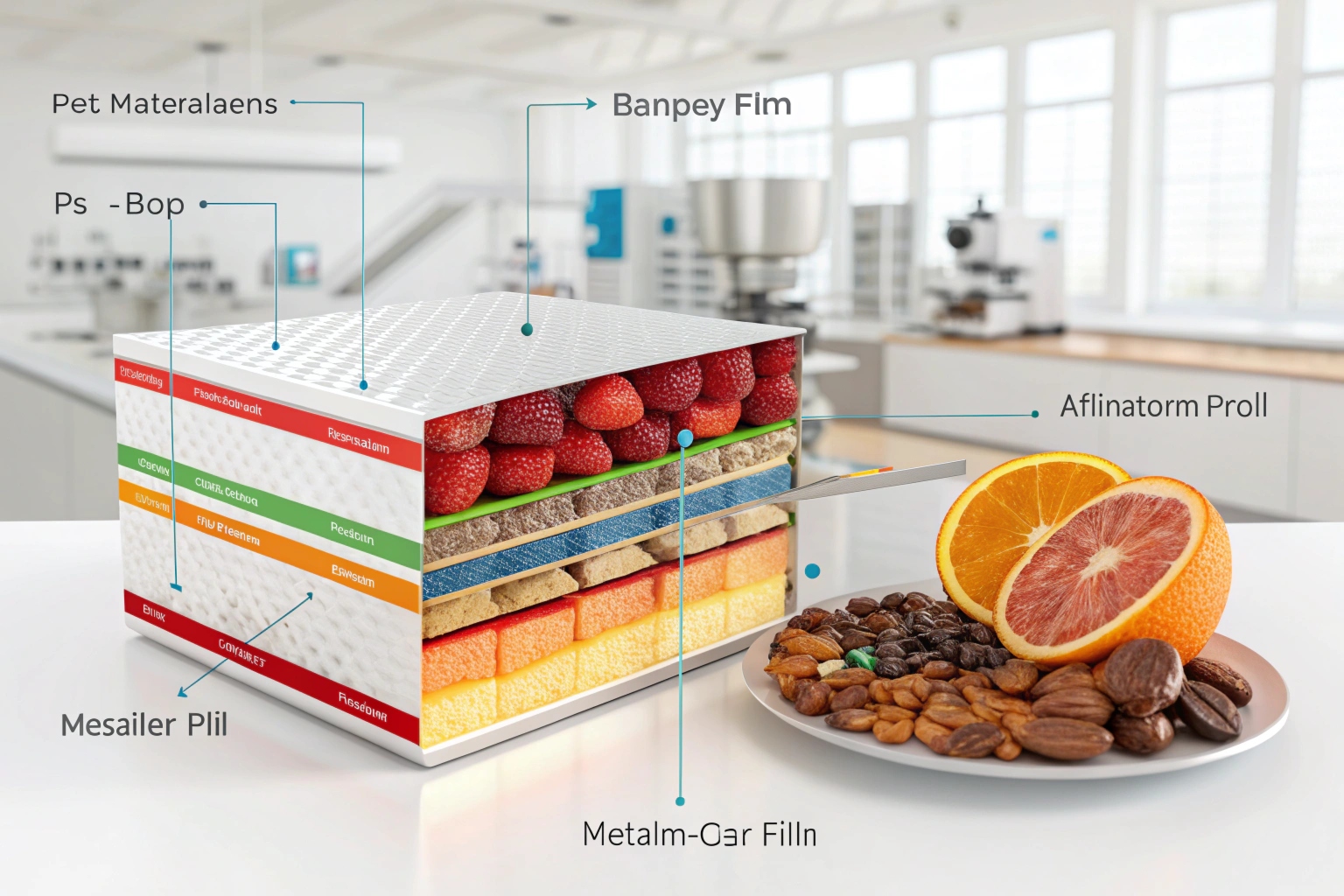

The five most common materials in dried fruit packaging are PET, PE, BOPP11, metallized film, and aluminum foil. Each plays a different role.

PET (Polyethylene Terephthalate)

- Use: Outer printable layer

- Strengths: Stiff, heat-resistant, clear

- Weakness: Moderate barrier

PE (Polyethylene)

- Use: Inner sealing layer

- Strengths: Food-safe, sealable

- Weakness: Weak oxygen barrier

BOPP11 (Biaxially Oriented Polypropylene)

- Use: Outer or inner film

- Strengths: Clear, low cost

- Weakness: Low barrier, not great alone

Metallized Film

- Use: Barrier middle layer

- Strengths: Blocks light, oxygen, moisture

- Weakness: Not transparent

Aluminum Foil5

- Use: High-barrier inner layer

- Strengths: Best barrier

- Weakness: Can’t see product unless a window is added

Packaging layer diagram Which type of packet is used to store dry fruits?

Stand-up pouches12, 8-side seal bags, and vacuum pouches are commonly used. Stand-up pouches12 with zipper and window offer the best balance for most retail use.

Packet type breakdown

| Packet Type | Barrier Strength | Display Style | Best Use |

|---|---|---|---|

| Stand-up pouch | High | Shelf | Retail sales |

| 8-side seal bag | High | Shelf | Bulk or premium |

| Flat pouch | Medium | Lay-flat | Budget or sample |

| Vacuum pouch | Very High | Flat | Export or bulk storage |

Display options

- Euro slot or round hole: Hang from hooks

- Clear window: Show the product

- Matte or glossy finish: Brand style

Why stand-up pouches are preferred

They combine strong materials, good printing area, and flexible features like zippers and windows. They also stand out on shelves.

Conclusion

Use clear PET/PE film for short-term dry fruit packaging under 6 months. For 12–24 months, go with metallized film. For even longer life, pure aluminum foil is the safest. A well-placed window and hang hole can improve shelf impact without harming protection.

-

Explore how moisture-proof packaging can significantly extend the shelf life of dried fruits. ↩ ↩

-

Find out how metallized films enhance the protection of dried fruits against spoilage. ↩

-

Learn about the critical role oxygen barriers play in preserving the quality of dried fruits. ↩

-

Discover the relationship between packaging materials and the longevity of dried fruit products. ↩ ↩

-

Understand why aluminum foil is considered one of the best materials for preserving dried fruits. ↩ ↩ ↩

-

Discover the top materials that ensure the quality and longevity of dried fruits. ↩

-

Explore the impact of humidity on dried fruit quality and how to mitigate its effects. ↩

-

Learn about the significance of WVTR in ensuring the quality of dried fruits. ↩

-

Explore how OTR impacts the freshness and flavor of dried fruits. ↩

-

Find out how proper sealing techniques can enhance the shelf life of dried fruits. ↩

-

Understand the role of BOPP in creating cost-effective and clear packaging solutions. ↩ ↩

-

Learn why stand-up pouches are a popular choice for retail dried fruit packaging. ↩ ↩