Every day I help pet food brands choose the right laminated roll for their products. Many ask how to custom pet food laminated roll1 that works in real production and meets barrier requirements2.

To custom pet food laminated roll1, you decide structure, materials, printing, lamination, film curing, and slit into rolls to your specified meters. I provide pre‑laminated roll stock3; you use your bag machine or automatic packer to form bags.

I want to walk you through how we do this at IMIPAK4 and explain why laminated rolls are a smart choice for many pet food makers.

What materials are used for pet food packaging?

When you design a pet food pouch or roll, choosing materials is the first step. Materials determine strength, barrier, seal, and print quality.

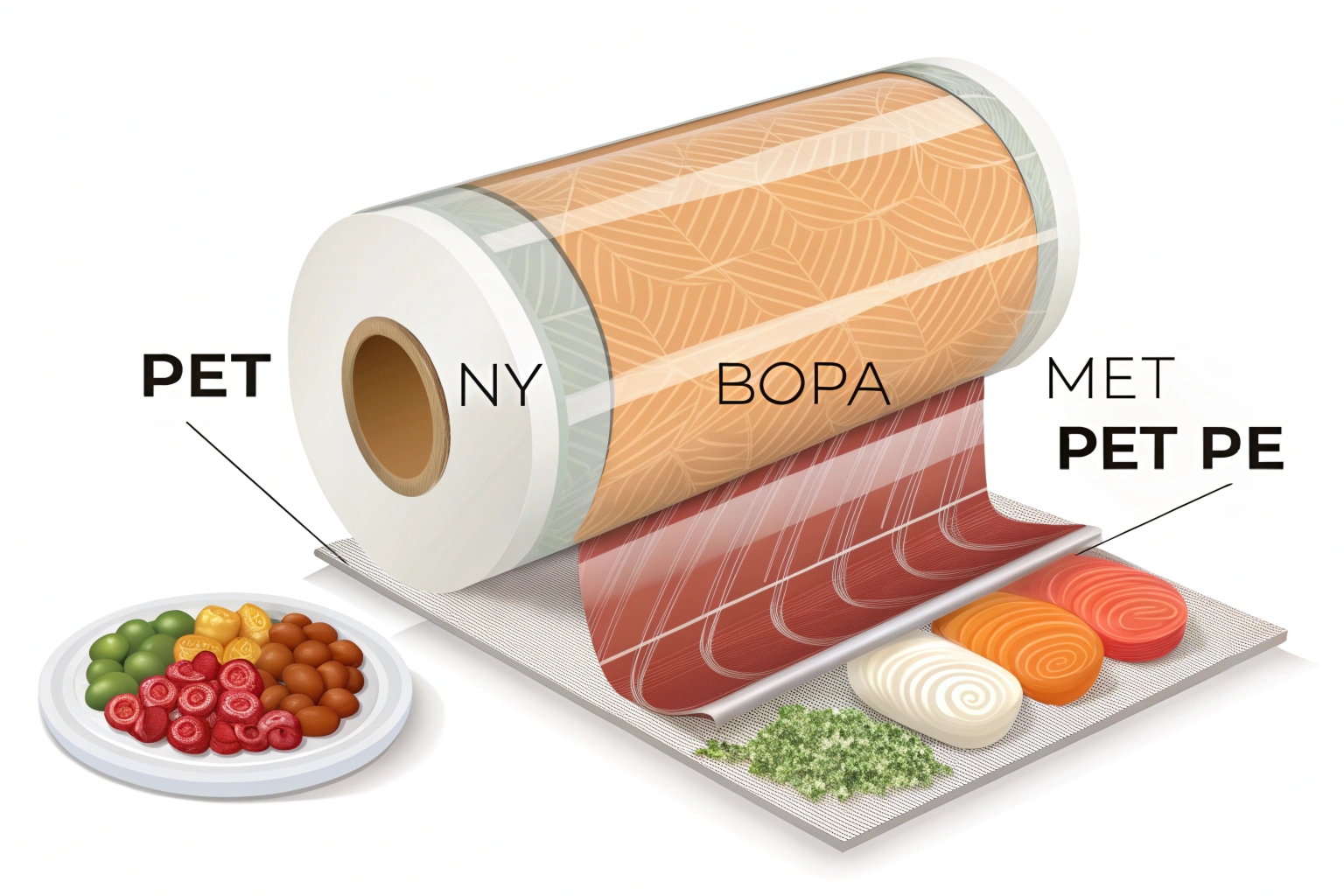

Common materials for pet food packaging5 include PET, BOPA, NY, MET PET, and PE. Each contributes specific properties like print surface, barrier, puncture resistance6, and heat sealability.

Why material choice matters for pet food rolls

When we custom a laminated roll, we look at oxygen and moisture barrier7 first. Pet food needs protection from oxygen and humidity to stay fresh during long transport and storage. That is why barrier layers like metallized films8 or nylon are common.

We also think about print quality. High quality printed film attracts customers on shelf. PET and BOPA give sharp graphics and strong adhesion for ink.

Seal strength matters too. The material at the innermost layer should seal well on your bag machine. PE or modified PE is usually the heat seal layer.

| Layer | Role |

|---|---|

| PET (Polyester) | Printable surface, strength, stiffness |

| BOPA (Biaxially Oriented Polyamide/Nylon) | Puncture resistance, strength |

| NY (Nylon) | Toughness, barrier reinforcement |

| MET PET (Metallized PET) | Oxygen/moisture barrier |

| PE (Polyethylene) | Heat seal layer |

PET — Durable print layer

PET is our go‑to material for outer surface printing. It holds ink well and resists scratches. That makes your graphics stay vibrant.

At IMIPAK4 we often use 12–15 mic PET for outer layers. These films give a stable surface for flexo or gravure printing9.

Nylon/BOPA — Strength and puncture resistance6

Pet food often has hard kibble edges. Laminated films without tear resistance can fail. That is where nylon (or BOPA) helps. Nylon increases toughness and reduces bag failure.

Large pet food makers prefer nylon reinforced structures for 5 kg and above packs.

Metallized PET — Barrier boost

A metallized layer boosts oxygen and moisture barrier7 without the cost of foil. We apply metallized PET inside the lamination to strengthen barrier properties.

For many pet food products, metallized PET delivers enough barrier for shelf life expectations.

PE — Heat seal layer

The inner layer that touches product is usually PE. It must seal on your bag machine or automatic packer. We customize PE thickness based on your sealing equipment and fill weight.

If you plan to make center‑seal bags, we tailor the PE seal layer to your machine’s requirements.

What are 5 materials used in food packaging?

Pet food is part of a bigger world of food packaging. Five materials dominate in flexible food packaging.

PET, NY (Nylon), BOPA, MET PET, and PE are the top five materials in food packaging. These materials strike a balance of barrier, strength, cost, and processing ease.

Material 1 — PET (Polyester)

PET stands for polyethylene terephthalate. It is widely used for outer printable film. PET has good dimensional stability, ensuring consistent roll width and print registration. For laminated rolls, PET gives high‑quality graphics and protects ink.

Material 2 — NY (Nylon)

Nylon adds puncture resistance6 and toughness. In many food and pet food applications, nylon resists stress cracks during packing, pallet stacking, and transport. When you custom a roll for heavy products, nylon is often essential.

Material 3 — BOPA (Biaxially Oriented Polyamide)

BOPA is another form of nylon, stretched in two directions. BOPA films offer high tensile strength10 and good clarity. We use BOPA when customers request specific toughness and reduced oxygen transmission.

Material 4 — MET PET (Metallized PET)

Metallized PET gives barrier similar to aluminum foil but at a lower cost and weight. We often recommend MET PET for pet food where oxygen and moisture barrier7 are priorities. Films with metallized layer maintain shelf stability.

Material 5 — PE (Polyethylene)

PE is the workhorse sealant layer. It provides heat sealability and toughness at the inner surface of the laminate. We adjust PE type and thickness to match your bag machine or vertical form fill seal (VFFS) machine.

How materials work together

In a laminated roll, these materials work as a team. PET or BOPA is the outer layer for print and strength. MET PET or foil gives barrier. PE seals the product. Nylon adds puncture resistance6. The lamination binds them into a single roll stock.

Material choice impacts cost too. Higher barrier materials cost more. At IMIPAK4 I always help customers balance cost and performance based on product needs.

Do you need a bag machine or automatic packaging machine to use laminated roll?

Many customers ask if they must own a bag machine or automatic packer to use laminated rolls. The answer depends on your production plan.

You do need bag making or automatic packaging equipment to convert laminated roll into bags. If you don’t have one, finished pouches11 might be a better choice.

Why equipment matters

A laminated roll is pre‑printed and pre‑laminated film. It still needs forming, sealing, and filling. That happens on your bag machine or automatic packer.

Without equipment you can’t turn roll stock into sealed pet food bags. For some small brands this step is a barrier.

If you don’t own a machine, I recommend finished pouches11. They arrive ready to fill and seal.

What machines work with laminated rolls

- VFFS (Vertical Form Fill Seal) — forms center sealed bags from roll

- Horizontal formers — for doy bags or quad seal bags

- Automatic pouch packers — for pre‑made bags

At IMIPAK4 we customize roll width based on your specific machine model and bag style.

Why large pet food makers choose rolls

Large pet food manufacturers usually have high capacity bag machines. They prefer laminated rolls because:

- Rolls reduce packaging cost per unit12.

- Rolls allow consistent print and barrier quality.

- Rolls fit high‑speed machines without frequent changeovers.

We work closely with customers to set up roll specs that match their equipment.

When finished pouches11 make sense

If you are new or have low output, finished pouches11 save you the cost of machines. You pay a bit more per unit, but you don’t need:

- Bag machine

- Operator training

- Maintenance

I often tell new brands to start with pouches. Later, they can switch to rolls when scale grows.

How IMIPAK4 handles custom laminated roll process13

At IMIPAK4 we refine every step of the laminated roll process. From printing to lamination to slitting.

Our custom process includes proofing, plate making, printing, lamination, curing, and slitting into your required roll length. We ensure quality and consistency every step.

Step 1 — Structure design and consultation

When a customer contacts me, we start with product info:

- Product type

- Fill weight

- Barrier needs

- Bag style

- Machine type

From this I choose materials and structure. This step ensures the film meets functional requirements.

Step 2 — Printing and color proof

We prepare plates and do a proof sample. You approve color and design before full print run.

Good print setup avoids waste and ensures sharp graphics.

Step 3 — Lamination

After printing the films, we laminate layers together. We often use solventless or solvent‑based lamination depending on structure.

Lamination bonds materials so they act as one film. Proper lamination prevents delamination during bag making.

Step 4 — Film curing

After lamination, the film needs drying or curing. This stabilizes adhesive and prevents issues on your bag machine.

Some materials like nylon or metallized films8 need specific curing conditions.

Step 5 — Slitting into rolls

Finally we slit into rolls with your specified:

- Width

- Core size

- Meters per roll

This is where customization really shows. If you need 500 m per roll or 1000 m per roll, we cut it.

Quality checks

Before shipment we test:

- Tensile strength

- Seal strength

- Barrier (O2 and moisture)

- Visual inspection

We only ship rolls that meet specs.

Common mistakes customers make with laminated roll

I see recurring issues when customers use laminated rolls without proper planning.

Common mistakes include wrong width, poor seal layer choice14, ignoring machine capability, and inadequate barrier planning15. These lead to rejects or production slowdown.

Mistake 1 — Ordering wrong width

If width doesn’t match bag machine, material wastes and downtime increase. Always confirm your machine’s film width and bag style.

Mistake 2 — Ignoring seal layer

The wrong PE type can lead to weak seals. I always ask for your sealing temp range and press time before recommending structures.

Mistake 3 — Skipping barrier planning15

Some brands under‑estimate oxygen barrier needs. Pet food with high fat content can go rancid if barrier is weak. That’s why I often suggest metallized or foil option for longevity.

Mistake 4 — Overlooking splice control

Too many splices in roll cause machine stops. I control the number of splices for export markets. This reduces downtime and scrap.

Conclusion

Custom laminated pet food roll requires correct materials, equipment matching, and expert process control. At IMIPAK4, I guide you from structure to finished rolls, ensuring performance and production success.

-

Explore this resource to learn the step-by-step process of creating custom laminated rolls for pet food. ↩ ↩

-

Understanding barrier requirements is crucial for maintaining pet food freshness; this link provides essential insights. ↩

-

Discover the benefits of using pre-laminated roll stock for efficient pet food packaging. ↩

-

Learn about IMIPAK's expertise in custom packaging solutions for the pet food industry. ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Learn about the various materials that enhance the quality and durability of pet food packaging. ↩

-

This resource highlights the importance of puncture resistance in maintaining product quality. ↩ ↩ ↩ ↩

-

This resource explains the significance of barriers in preserving pet food quality during storage. ↩ ↩ ↩

-

Learn how metallized films can improve barrier properties and shelf life for pet food. ↩ ↩

-

Discover the differences between these printing techniques and their applications in pet food packaging. ↩

-

Understanding tensile strength is crucial for ensuring the durability of packaging materials. ↩

-

Explore the advantages of using finished pouches for small-scale pet food packaging. ↩ ↩ ↩ ↩

-

Understanding packaging costs is essential for optimizing production efficiency and profitability. ↩

-

This link provides a comprehensive overview of the steps involved in creating custom laminated rolls. ↩

-

This resource offers guidance on selecting the appropriate seal layer for optimal performance. ↩

-

Learn about the importance of barrier planning to prevent spoilage in pet food products. ↩ ↩