As a flexible packaging manufacturer working daily with coffee roasters1 and importers around the world, I’m often asked one clear question: how do I custom flat bottom coffee bags2 in China? After 15+ years in this industry, I’ve seen what works and what fails. This article walks you through all the key steps, from design to sealing, and the real risks to watch out for.

To custom flat bottom coffee bags2 in China, you must understand bag structures, materials, printing, sealing methods, and production risks3. Flat bottom and 8‑side seal zipper bags4 look more premium than stand up or 4‑side sealed bags, and with the right factory partner, you get quality packaging for 200g–2kg.

One buyer once told me he ordered flat bottom bags that looked great in photos, but on the filling line they kept falling over and damaging seals. That taught me to always stress practical producibility, not just graphics.

How do I make my own coffee bags?

Many people think making their own coffee bags is as simple as cutting and sealing film. Yes, you can make bags at home, but there are limits.

You can make simple coffee bags at home using a heat sealer5 and pre‑laminated films, but to make professional, custom printed coffee bags6—especially flat bottom or 8‑side seal zipper bags4—it is far more efficient and reliable to work with a professional packaging factory in China7 that has bag making machines and printing presses.

Dive Deeper — Making Coffee Bags at Home vs Factory

Tools Needed for Home Bag Making

| Tool | Purpose |

|---|---|

| Heat Sealer | Seal the bag edges |

| Scissors / Cutter | Cut film to size |

| Ruler / Template | Ensure consistent size |

| Pre‑made Films | Already laminated films simplify sealing |

When Home Making Works

If you roast at home or make gifts, simple stand up pouches or basic flat bags sealed at the top can be made with a household impulse sealer. You can even use a flat iron or hair straightener in a pinch (more on that later). Just keep expectations realistic.

Limits of Home Making

- Printing: Home setups can’t print custom logos or high‑resolution designs.

- Barrier Properties: Professional bags combine PET/foil/PE layers8 for aroma and moisture protection—hard to reproduce at home.

- Strength & Consistency: Flat bottom bags require accurate folding and multiple seals that hand tools can struggle with.

For retail quality and shelf appeal, partnering with a Chinese factory ensures consistent bags that run smoothly on your filling line.

How to design a coffee bag?

Design is more than how the bag looks. It’s also about structure, usability, and production feasibility.

To design a coffee bag, you need to define your brand identity, choose bag structure (flat bottom, stand up, quad or 8‑side seal), select materials, and prepare artwork that fits printing specs9 and production tolerances.

Dive Deeper — Coffee Bag Design Essentials

Brand Identity and Target Market

Your colors, fonts, and imagery should reflect your brand mood—premium, rustic, playful, or minimalist. Design must also be legible on shelves under real lighting.

Choosing the Right Structure

| Structure | Characteristics | Best For |

|---|---|---|

| Flat Bottom | Stands very well, premium look | Retail shelves |

| 8‑side Seal / Quad Seal | Very premium, structural strength | High‑end brands |

| Stand Up Pouch | Flexible and cost‑effective | Small batch or low price |

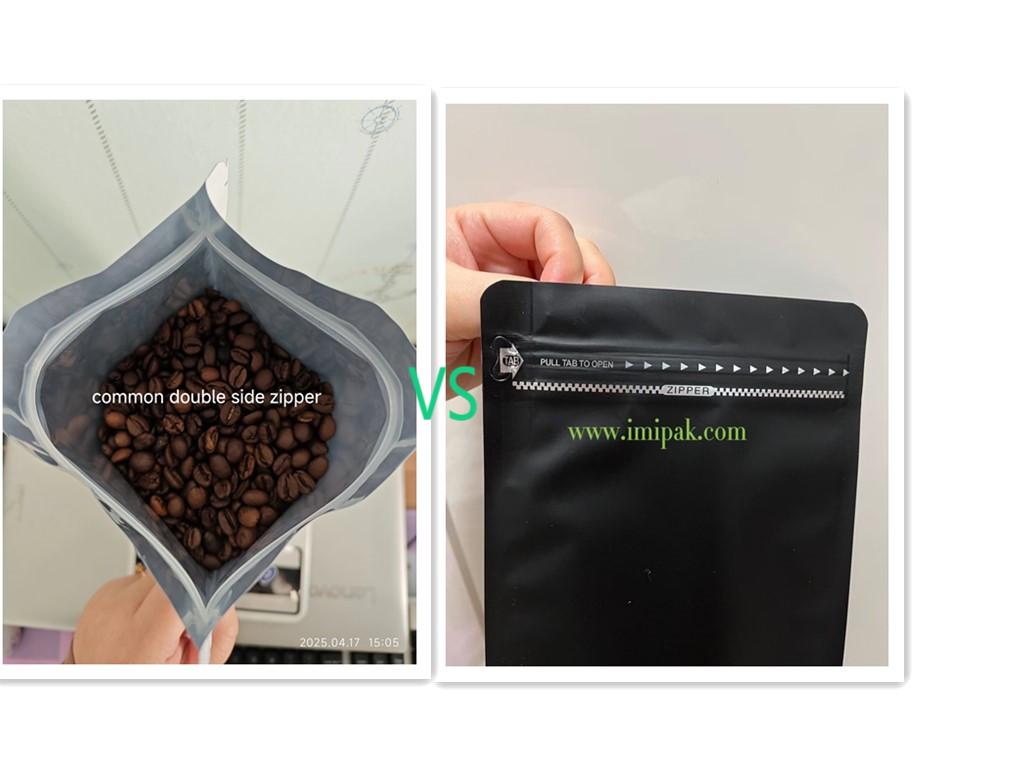

I’ve noticed 8‑side seal zipper bags4 are becoming more popular for coffee packaging. They look more substantial than classic stand up, 4‑side, or center seal bags. They cost a bit more, but on shelf they attract more attention. For similar sizes—200g, 250g, 500g, 1kg, 1.5kg, 2kg—8‑side seal bags give a premium feel.

Artwork and Panel Layout

A flat bottom bag typically has front, back, bottom, and side panels. For 8‑side seal bags with tear notch zippers, the front/back/bottom are one print plate, and each side panel is another. That means separate plate fees. Accurate dielines10 are critical. A common mistake is misaligned art, which leads to wasted film.

How to make a coffee bag wallet11?

A coffee bag wallet11 is essentially a small pouch that opens and folds like a wallet—useful for sample packs or gift sets.

To make a coffee bag wallet11, you need a laminated film with good foldability, a precise dieline, and careful sealing on all edges so each compartment holds coffee without leaks.

Dive Deeper — Wallet‑Style Coffee Bags

These bags often use the same materials as full‑size bags, but the design must allow multiple folds without breaking the barrier layers. You need to plan:

- Where coffee goes

- Where seals go

- How the wallet opens

This requires careful drafting and often prototype runs to test durability.

How to seal a coffee bag with an iron?

Some small roasters ask if a clothing iron can seal a coffee bag.

You can seal a coffee bag with an iron by setting it to high heat and pressing firmly along the edge, but the results are inconsistent and often weak compared to a proper heat sealer5. You risk burning film or making incomplete seals.

Dive Deeper — Iron Sealing Tips

If you must use an iron:

- Place a flat board under the bag edge.

- Use the highest dry heat (no steam).

- Press evenly for several seconds.

Problems include:

- Uneven seals

- Film distortion

- Weak seals that fail under stress

For reliable seals, especially on laminated films used for barriers, a real heat sealer5 is worth the investment.

What is the best material for coffee bags?

Choosing material determines barrier performance, print quality, and seals.

The best materials for coffee bags are multi‑layer laminations12—usually PET (or OPP) + aluminum foil + PE or CPP—which give strong barrier against oxygen and moisture, plus good print surfaces.

Dive Deeper — Material Components Explained

Typical Lamination Structure

| Layer | Function |

|---|---|

| PET / OPP | Print surface and strength |

| Aluminum Foil | Barrier to oxygen and moisture |

| PE / CPP | Heat seal layer |

For flat bottom and increasingly popular 8‑side seal bags with tear‑notch zippers, we often use:

- Front / back / bottom: Matt OPP + aluminum + PE

- Side panels: PET with matte varnish + aluminum + PE

Why this mix? When you add tear‑notch zipper and need higher sealing temperatures, pure OPP struggles because it’s not tolerant of high heat and can bond incorrectly. PET matte varnish on sides avoids that, giving clean seals. This is something I learned handling hundreds of production runs.

Printing Considerations

Good print quality comes from PET or OPP layers that accept inks well. Matte finishes are popular—they feel premium and reduce glare on shelf.

What is the 80/20 rule for coffee?

In coffee roasting and packaging circles, the 80/20 rule often refers to focusing on the small number of variables that create most results.

In coffee roasting, the 80/20 rule usually means that 80% of the flavor profile results from 20% of the roast variables. For packaging, this translates to prioritizing barrier quality and seal integrity13 over minor decorative features.

If your bag looks beautiful but fails aroma protection or seal strength, customers notice first on flavor loss.

How to seal a bag with a flat iron?

Some hobbyists ask if a flat iron tool (like for hair) can do the job.

A flat iron can seal bags only if it reaches and holds sufficient heat and pressure. Like clothing irons, it’s inconsistent and can damage laminated films, so it’s not recommended for real packaging.

Dive Deeper — Flat Iron Sealing

- Heat may not be even across the surface.

- Pressure is hard to control.

- You risk warping or tearing barrier layers.

Packaging factories use calibrated heat seal bars with precise temperature and pressure settings. That consistency matters for barrier performance.

Do coffee bags need a valve?

Fresh roasted coffee releases CO₂ for days after roasting. That gas buildup can burst bags or compromise seals.

Yes, most roasted coffee bags benefit from a one‑way degassing valve14. It lets CO₂ escape while blocking oxygen, preserving freshness and preventing bags from swelling or leaking.

Dive Deeper — Valve Function

Valves are especially important when:

- Shipping long distances

- Roasts are fresh

- Coffee is medium or dark roast

Some buyers skip valves to save cost, but for specialty coffee, valves help protect aroma and texture.

Can I use a hair straightener to seal coffee bags?

Like irons and flat irons, hair straighteners are sometimes tested.

You can use a hair straightener to seal coffee bags in a pinch, but it’s unreliable. Temperature control is rough, surfaces are narrow, and films can warp or not seal fully.

Dive Deeper — Why It’s Not Ideal

- Narrow contact area makes uneven seals.

- Clamp pressure is hard to keep consistent.

- You risk damaging barrier layers.

Good for casual experimentation, not real packaging.

What is the best heat sealer5 for coffee bags?

Choosing the right sealer depends on volume and film type.

Impulse bar sealers with adjustable temperature are great for small batches or labs, while continuous band sealers suit higher output. Vacuum chamber sealers add freshness by removing air before sealing.

Dive Deeper — Heat Sealer Options

| Type | Best For |

|---|---|

| Impulse Bar Sealer | Small batches, home use |

| Continuous Band Sealer | Mid to high volumes |

| Vacuum Chamber Sealer | Maximized freshness |

Ensure sealers have temperature control so they adapt to thick laminated films used in premium bags.

How long will coffee last in a sealed bag?

Freshness depends on roast, storage, and bag quality.

Coffee in a sealed, barrier bag with a valve can stay fresh for 3–6 months or longer if stored cool and dark, but the peak flavor is usually within the first month after roast.

Dive Deeper — Factors Affecting Shelf Life

- Roast date vs packaging date

- Presence of a one‑way valve

- Storage conditions (heat, light, humidity)

Barrier bags slow oxidation and moisture ingress, preserving flavor longer.

How about the risk when making flat bottom coffee bags2?

Flat bottom bags are popular, but they have risks if design and production aren’t aligned.

Common risks include seal failures, film delamination, improper folding, and artwork misalignment15. Experienced factories mitigate these with controlled processes, quality checks, and accurate dielines10.

Dive Deeper — Common Production Risks

Seal Failures

If sealing temperatures or pressures are off, bags can open under stress or on the filling line.

Delamination

Cheap films may separate under heat and stress, exposing coffee to air.

Artwork Misalignment

Without proper dielines10, printing panels may wrap incorrectly, wasting film.

Practical Example from Factory

A buyer once sent artwork without clear panel mapping, and we produced hundreds of bags with side panels printed upside down. We now always confirm dielines10 before production.

How to seal coffee bags at home?

Many hobby roasters want to seal small batches at home.

At home, an impulse heat sealer5 or vacuum sealer with adjustable temperature will give the best results. Consistent pressure and right heat are key.

Dive Deeper — Step‑by‑Step Home Sealing

- Prepare laminated coffee bag film.

- Place coffee inside, leaving headspace.

- Adjust sealer temperature to match film.

- Press and hold until the seal completes.

- Check seal strength by gently tugging.

Avoid wrinkles or folds at the seal line; they weaken strength.

Conclusion

Custom flat bottom coffee bags2 in China require careful choices in structure, materials, design, sealing methods, and quality control. Understanding how materials like PET, aluminum, and PE work together—and how structures like 8‑side seal zipper bags4 differ from classic stand up pouches—gives you an edge in sourcing packaging that looks great and performs well.

-

Learn how coffee roasters select packaging that enhances freshness and brand identity. ↩

-

Explore the advantages of flat bottom coffee bags for premium packaging and shelf appeal. ↩ ↩ ↩ ↩

-

Understand the risks involved in coffee bag production and how to mitigate them. ↩

-

Understand why 8-side seal zipper bags are becoming popular for coffee packaging. ↩ ↩ ↩ ↩

-

Find out which heat sealers are most effective for sealing coffee bags reliably. ↩ ↩ ↩ ↩ ↩

-

Discover how custom printing can elevate your coffee brand and attract customers. ↩

-

Get tips on selecting a reliable packaging factory in China for your coffee bags. ↩

-

Discover how these layers work together to protect coffee from external elements. ↩

-

Understand the printing specifications needed for high-quality coffee bag designs. ↩

-

Learn about the significance of dielines in ensuring accurate packaging production. ↩ ↩ ↩ ↩

-

Explore the concept of coffee bag wallets and their practical uses. ↩ ↩ ↩

-

Understand the benefits of multi-layer laminations for coffee bag durability. ↩

-

Learn why maintaining seal integrity is crucial for preserving coffee quality. ↩

-

Discover how a degassing valve preserves coffee freshness during storage. ↩

-

Explore common causes of artwork misalignment and how to avoid them. ↩