In recent years, more roasters and private label brands have been asking me about laminated rolls1. Are they still the best choice for coffee packaging2?

Laminated rolls remain the top choice for coffee packaging2 due to their barrier performance3, customizability, and adaptability to eco trends like recyclable mono-material films4.

I’ve helped both startups and established brands choose between laminated rolls1 and pre-formed bags. The trends I see today are changing how we think about materials, sustainability5, and shelf life6.

What is the suitable material for coffee packaging2?

Materials can make or break your product. Poor barrier? Your beans go stale fast. Wrong sealing layer? Bags burst in transit. So what should we use?

The most suitable materials for coffee packaging2 are laminated films combining PET, foil, or EVOH7 for barrier, and PE for sealing, with optional kraft for brand effect.

Dive Deeper

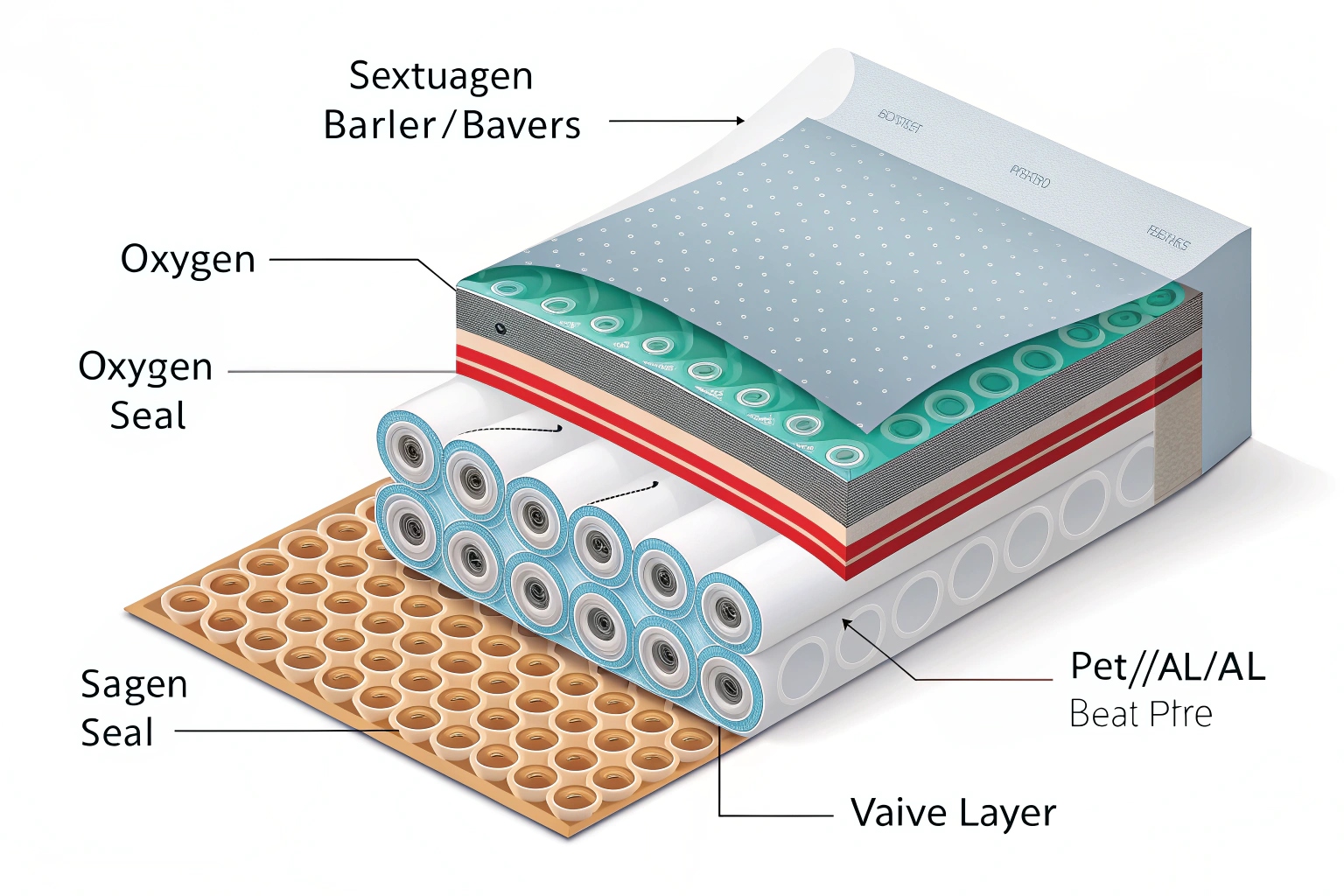

Common material combinations in laminated rolls1

| Structure | Barrier Layer | Sealing Layer | Features |

|---|---|---|---|

| PET/AL/PE | Aluminum foil | Polyethylene | Excellent oxygen and light barrier |

| PET/VMPET/PE | Metallized PET | PE | Lower cost, decent protection |

| Kraft/PET/PE | Paper aesthetic | PET barrier | Natural look with good printability |

| PET/EVOH7-PE | EVOH7 (non-metal) | PE | Recyclable barrier laminate |

Why these layers matter

- PET offers strength, print clarity, and heat resistance

- Foil or metallized PET prevents oxygen, light, and aroma escape

- PE allows reliable heat sealing and food-safe contact

- EVOH7 provides barrier with recyclability (used in mono-material laminates)

Choosing the wrong structure leads to complaints: “My coffee lost its smell” or “The bag exploded when heat sealed.” I’ve heard it all. That’s why understanding structure is essential.

Which packaging is better for preserving the quality of roasted coffee beans and why?

After roasting, beans continue to release CO₂ and lose freshness. Packaging is your only defense.

Coffee packaging with a degassing valve8, high oxygen barrier, and strong seal layer—like laminated foil pouches—is best for preserving roasted beans.

Dive Deeper

The enemies of fresh coffee

- Oxygen: Causes staling and flavor loss

- Moisture: Promotes mold and bean degradation

- UV light: Breaks down oils and aroma

- Time: Oxidation increases over weeks

How laminated rolls1 help

| Feature | Benefit |

|---|---|

| Foil barrier | Blocks oxygen and light |

| One-way valve | Releases CO₂ without letting air in |

| Heat-seal layer | Prevents leaks, extends shelf life6 |

| Printable surface | Allows branding without affecting performance |

Packaging test results

I once worked with a Japanese importer who tried switching from PET/AL/PE to PET/VMPET/PE. After one month, complaints increased: “Coffee smells flat.” We tested oxygen levels—sure enough, higher permeability was the cause.

When flavor and aroma matter, never compromise on barrier quality.

What is the most sustainable coffee packaging2?

Sustainability is the hottest topic right now. But let’s be clear—eco-friendly doesn’t mean less effective.

The most sustainable coffee packaging2 uses mono-material films (like PE/PE) that are recyclable, or compostable bio-laminates9 made from PLA and paper, with minimal inks and coatings.

Dive Deeper

Recyclable vs compostable

| Type | Examples | Notes |

|---|---|---|

| Recyclable | Mono PE/PE, Mono PP | Needs store drop-off or special sorting |

| Compostable | PLA/PBAT, paper/cellulose | Industrial composting often required |

What works best for coffee?

- Mono-PE films with EVOH7 coating: keeps aroma in, air out, and can be recycled in soft plastic programs.

- Kraft-paper with bio-laminate inner layer: compostable, but not always heat-resistant or durable.

What we use at IMIPAK

We now offer recyclable laminated rolls1 (mono-PE), which work well on VFFS machines and maintain up to 95% of traditional foil barrier performance3—good enough for most coffees under 3-month shelf life6.

For longer-term storage, compostable options may fall short. I always help customers weigh marketing appeal vs technical need.

What are the eco-friendly food packaging trends?

Coffee isn’t the only sector going green. Let’s look at broader trends in food packaging—many apply to coffee as well.

Eco trends include recyclable mono-material films4, minimal packaging10, natural inks, refill systems, and digitally printed small-batch runs to reduce waste.

Dive Deeper

Top eco-packaging trends

1. Mono-material structures

- Easier to recycle (PE/PE, PP/PP)

- Avoid foil or glue-heavy laminates

2. Minimalist design

- Fewer colors = fewer chemicals

- Less ink = better recyclability

- Matte kraft + simple logo is back

3. Refill and reuse

- Rigid containers with flexible refill packs

- Brands use laminated rolls1 for refill pouches

4. Small batch printing

- Digital printing reduces MOQ and waste

- Works well with limited editions or seasonal blends

| Trend | Advantage |

|---|---|

| Mono-material | Easier to recycle, less contamination |

| Compostable | Great marketing angle, low carbon footprint |

| Low-ink designs | Safer for recycling, cheaper |

| Digital print | Reduces waste, matches demand |

At IMIPAK, we’re now combining digital printing11 with recyclable PE rolls—ideal for test runs with fast turnaround. A Singapore client recently launched five seasonal blends using one roll structure with variable artwork—no waste, no delay.

Conclusion

Laminated rolls continue to evolve—balancing performance and sustainability5. The right material preserves your roast, elevates your brand, and helps you meet customer and environmental demands. Choose smart. Ask questions. And always test before scaling up.

-

Explore how laminated rolls enhance coffee packaging with superior barrier performance and customizability. ↩ ↩ ↩ ↩ ↩ ↩

-

Discover the most effective materials for coffee packaging to ensure freshness and quality. ↩ ↩ ↩ ↩ ↩ ↩

-

Learn about the critical role of barrier performance in preserving coffee freshness and flavor. ↩ ↩

-

Understand the advantages of using recyclable mono-material films in coffee packaging. ↩ ↩

-

Stay updated on sustainable packaging trends that can enhance your brand's eco-friendly image. ↩ ↩

-

Learn how different packaging materials can extend the shelf life of coffee products. ↩ ↩ ↩

-

Explore the properties of EVOH and its role in creating effective barrier layers for packaging. ↩ ↩ ↩ ↩ ↩

-

Find out how a degassing valve helps maintain coffee freshness by managing CO₂ release. ↩

-

Learn about compostable bio-laminates and how they contribute to sustainable packaging solutions. ↩

-

Discover how minimal packaging can reduce waste and enhance product appeal. ↩

-

Explore the benefits of digital printing in reducing waste and improving packaging efficiency. ↩