I once thought sourcing pet food bags in China would be easy. But after talking with factories and shipping agents, I saw many hidden risks. I worried about quality, cost, and delays. But I also learned key lessons.

Before manufacturing pet food bags in China, I must know material choices1, waterproofing2, production process3, labeling4, and how ingredients5 are listed. These shape cost, safety, and brand trust.

Last month, I visited a packaging factory in Guangdong. I saw raw materials piled high. Machines stamping logos. Bags being heat‑sealed. I smelled chemicals, and got worried about food safety6. But I also saw strong systems and quality tools. Those visits taught me what to ask before I order.

What are pet food bags made of?

I used to assume all pet food bags are the same. They are not. The base material affects shelf life, cost, looks, and supply risk.

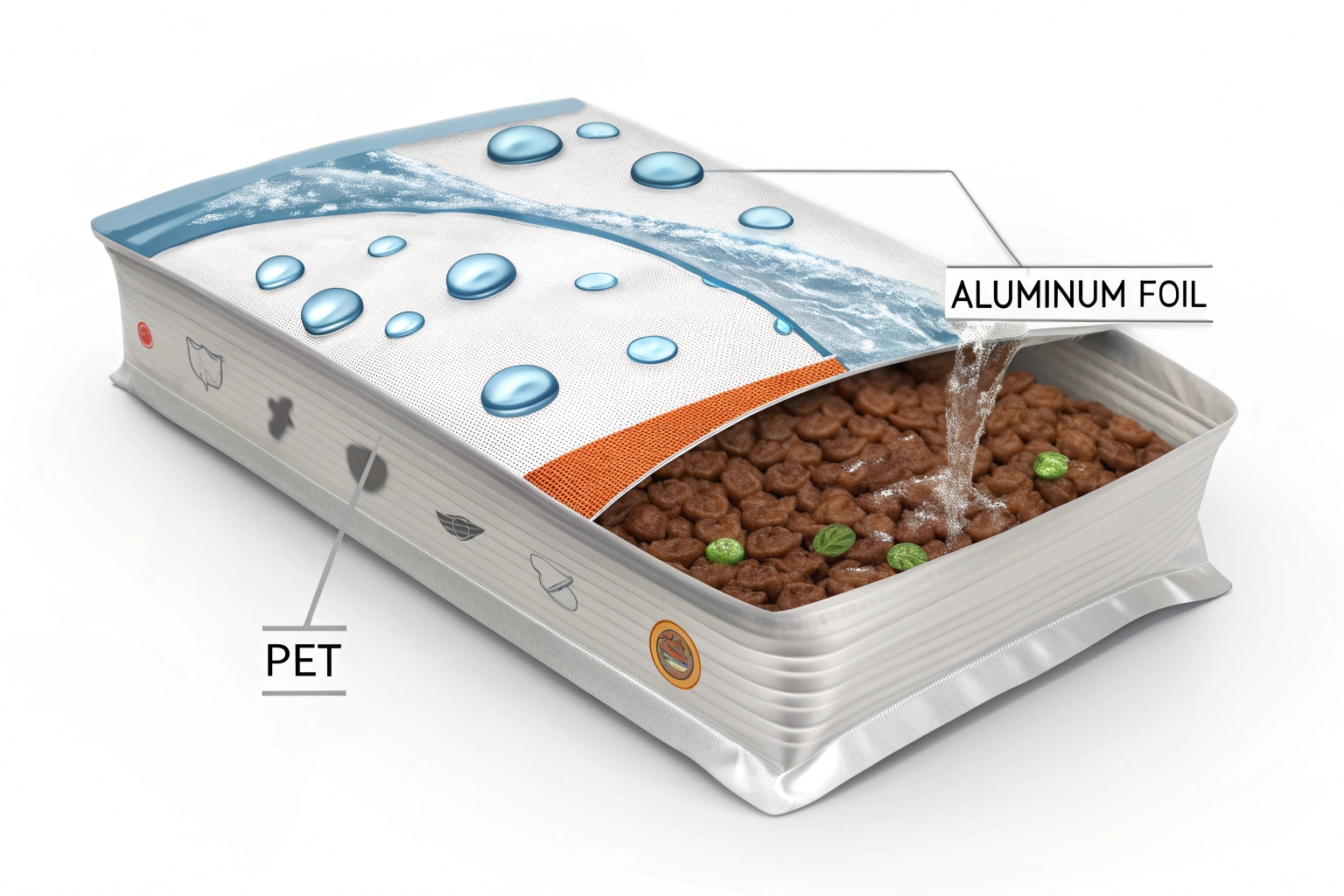

Pet food bags often use multi‑layer laminates combining plastic films (like PET, PE), foil for barrier, or paper layers. Sometimes mono‑films, kraft paper7, or compostables appear.

Dive Deeper

H3: Multi‑layer laminates structure

In China, many factories use PET (polyethylene terephthalate) outer layer for print clarity, aluminum foil middle layer for light and oxygen barrier, and PE (polyethylene) inner layer for heat seal and moisture protection. This structure protects food well, especially high‑fat or moisture food. But you then have complex recycling problems.

H3: Mono‑films and single‑material choices1

To simplify manufacturing and improve recyclability, some brands pick one plastic type, like PP (polypropylene) or PE. Mono‑films are easier to recycle. They are lighter. They may cost less in shipping. But barrier performance might suffer unless thickness or coatings improve.

H3: Paper and kraft options

Kraft paper gives a natural, rustic look. Factories line paper with thin plastic or bio‑coating inside to reduce moisture, grease. Pure paper options are less common in moist or oily food. But for dry kibble, paper bags work well if combined with foil or inner liner.

H3: Compostable and bio‑based materials

Factories are starting to offer PLA, bio‑PE, or other bio‑films. These degrade under certain conditions. But cost is higher and supply is less stable. You need to check certification (e.g. compostable standard) and ensure local or buyer markets support composting infrastructure.

Table: Material types vs pros & cons

| Material Type | Advantages | Disadvantages |

|---|---|---|

| PET/foil/PE multi‑layer | Strong barrier, long shelf life, good print quality | Hard to recycle, heavier, more complex manufacturing |

| Mono‑plastic (PP, PE) | Easier recycling, lighter weight, lower cost | Barrier may be weaker, needs careful sealing |

| Kraft paper + liner | Natural look, eco appeal | May need inner liner, moisture control issues |

| Compostable / bio‑films | Green credentials, marketing advantage | Higher price, uncertain supply, certification needed |

What are the materials used in pet food packaging?

This extends from what bags are made of. Here I look at secondary and accessory materials: inks, adhesives8, zippers, etc.

In addition to base film or paper, packaging uses inks, adhesives8, barrier coatings9, zip locks10/zippers, gussets, printing varnishes, handles, and inner liners. All impact safety, cost, and appearance.

Dive Deeper

H3: Inks and printing techniques11

China factories may use solvent‑based, water‑based, UV or flexographic printing. Water‑based and UV are safer for food packaging but cost more. Ink migration (chemical moving from ink into food) must be controlled. I check for food‑grade ink certifications.

H3: Adhesives, sealants, lamination glue

Laminated layers require good adhesives8 or glue. These must also be food safe. Poor glue causes delamination or smell. Factories sometimes use cheaper glue to cut cost—risky decision.

H3: Barrier coatings inside materials

To block moisture, oxygen, or grease, factories apply aluminum foil or metallized films, or even coatings like PVDC. The choice depends on food type: dry vs oily vs wet. Better barrier costs more but protects freshness.

H3: Zippers, tear notches, valves, handles

Convenience features matter. Zip locks let users reseal. Tear‑notches for easy opening. Valves for fresh air release (in case of roasted‑type kibble). Handles help heavy bags. These features add cost and complexity.

H3: Inner liners or edible coatings

Sometimes inside liners are added to further protect from oil or moisture. Some coatings may even be edible for pet safety. I must check liner material compatibility with the food inside.

Are dog food bags waterproof?

Buyers expect dog food to stay dry. A wet bag ruins quality. So I need to understand waterproofing2 thoroughly.

Dog food bags generally are water‑resistant or waterproof on the outside; inside layers or liners must block moisture. True waterproofing2 comes from correct materials (plastic layers or metallization) and good sealing.

Dive Deeper

H3: Outer layer treatments and coatings

To repel water outside, bags often have a plastic (PET or PE) outer layer. Some apply varnish or lamination. For paper bags, wax or plastic coatings on the outer surface help water resistance. Without them, paper soaks, looks bad, becomes weak.

H3: Inner moisture barriers

Inside layers (foil, plastic) prevent moisture from reaching food. If you use kraft paper7 on outside, inner foil or plastic liner is essential. Otherwise, moisture from storage or shipping damages food.

H3: Sealing methods and heat seal strength12

Even with good materials, poor sealing ruins waterproofing2. Heat‑seals, ultrasonic seals, or laminations must be strong. If bag leaks at seams, protection fails. I always ask for seal test data (water spray, drop tests).

H3: Real conditions during transport

Weather, humidity, cargo stacking, rain in transit. Waterproofing that works in lab may fail in shipping. I ask the factory to simulate.

Table: Waterproof‑related factors

| Factor | Why it matters |

|---|---|

| Material outer layer | Keeps rain/humidity off |

| Inner liner/barrier | Protects food content |

| Seal strength | Prevents leaks at seams |

| Coatings / laminations | Adds extra water resistance |

| Transport conditions | Real tests prove effectiveness |

What is the process of manufacturing packaging in China?

Manufacturing involves many steps. Knowing them keeps cost low and quality high.

Typical process: design → material procurement → printing and lamination → pouch or bag forming → quality control13 → packaging and shipping. Each step carries risks and decisions I must make.

Dive Deeper

H3: Design and prototyping

I give the artwork in correct format (color mode, resolution). Factories may send proof or sample. Prototype lets me test look, prints, material feel.

H3: Material sourcing and supply chain risks14

Factory may source PET film from petrochemical suppliers, foil from metallization units, adhesives8 from chemical firms. Prices vary with raw material cost. Supply delays or substandard raw materials hurt final product.

H3: Printing, lamination, and drying

Printing uses flexo or gravure. After print, layers are laminated: film + foil + plastic or paper + liner. Then dried, flattened. Errors here show up later: color mismatches, delamination.

H3: Bag forming and features addition

After lamination, machines cut, seal, add zippers, add handles, make gussets. The sealing machines must be precise. If zipper misaligned, or handle weak, bag fails in use.

H3: Quality control and compliance

I inspect thickness, barrier tests (oxygen, moisture), seal strength12, print quality, food safety6 standards (e.g. for chemicals, PH, migration). Factories in China may have ISO, BRC, or other certifications. I check them.

H3: Packing, labeling4, export logistics

Finished bags are folded, packed into cartons. Labels outside must reflect content. Shipping involves customs, inspections. Delays or wrong documents cause problems.

How are ingredients5 listed on pet food containers?

Labeling determines trust, legal compliance, and buyer decision. I must understand rules and best practice.

Ingredients listed must follow buyer country law, show content by weight, use correct order, show allergen or risk info, and use clear, readable font. Mislabeling4 causes fines, returns, loss of brand trust.

Dive Deeper

H3: Order and weight percentage

Ingredients must appear in descending order by weight (before or after cooking, depending on jurisdiction). Major ingredients5 first. If “chicken meal” is used, percentage may be required.

H3: Legal requirements per target market

US, EU, Canada have different rules. For example, EU requires net weight, best before date, feeding instructions, name and address of manufacturer. I must tell factory what market this is for so label is correct.

H3: Allergen or risk statements

If ingredient may cause allergic reaction, label it clearly. Also state any preservatives or artificial additives. Sometimes pet owners care deeply about “no by‑products” or “grass‑fed” etc.

H3: Font size, clarity, multilingual labels

Label must be legible. Smallest font size per law. Some buyers want dual language (e.g. English + local language). Logos or graphics must not obscure important text.

H3: Nutrition facts and guarantee analysis

Many markets require “Crude Protein”, “Crude Fat”, “Crude Fiber”, “Moisture” etc. These must be accurate. Factories need to test pet food and supply those numbers.

Table: Label contents vs purpose

| Label Element | Purpose |

|---|---|

| Ingredient list | Tells buyer what is inside |

| Weight percentages | Shows how much of each ingredient |

| Nutrition analysis | Helps pet owner compare products |

| Allergen / additive info | Protects animal health and consumer trust |

| Legal / language info | Ensures compliance and avoids customs issues |

Conclusion

I must choose materials well, ensure waterproofing2, watch the full manufacturing process, use correct features, and label clearly before making pet food bags in China. If I do these right, I avoid risk, save money, and build trust with my customers.

-

Understanding material choices is crucial for ensuring quality and safety in pet food packaging. ↩ ↩

-

Explore waterproofing techniques to ensure your pet food remains fresh and safe from moisture. ↩ ↩ ↩ ↩ ↩

-

Learn about the production process to identify potential risks and improve quality control. ↩

-

Proper labeling is essential for compliance and building trust with consumers. ↩ ↩ ↩

-

Discover the legal requirements for ingredient listing to avoid fines and ensure transparency. ↩ ↩ ↩

-

Understanding food safety standards is vital for protecting consumer health and brand reputation. ↩ ↩

-

Kraft paper provides a natural look; explore its benefits and limitations for pet food. ↩ ↩

-

Choosing the right adhesives is crucial for maintaining food safety; find out more. ↩ ↩ ↩ ↩

-

Barrier coatings protect food quality; discover their role in pet food packaging. ↩

-

Zip locks enhance convenience for consumers; learn how they can improve your packaging. ↩

-

Explore safe printing techniques to ensure your packaging meets food safety standards. ↩

-

Seal strength is critical for waterproofing; learn how to ensure your bags are properly sealed. ↩ ↩

-

Effective quality control is essential for maintaining product integrity; learn best practices. ↩

-

Identifying supply chain risks can help you mitigate potential issues and ensure quality. ↩