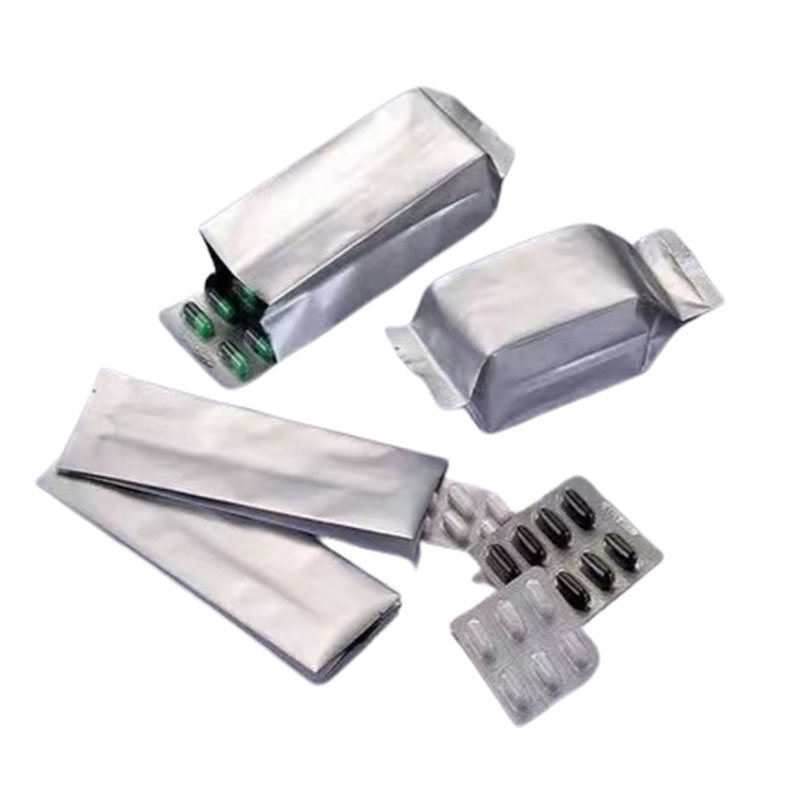

Pharmaceutical & Medical bag

Pharmaceutical packaging bags must ensure the safety, efficacy, and stability of the medication they contain, as well as comply with regulatory requirements.

Additional information

| color | custom |

|---|---|

| size | custom |

| description | Pharmaceutical or medicine bag |

| valve | no degassing valve |

| stock | NO |

Product details

Flexible packaging bags for pharmaceutical and medical applications need to meet specific requirements to ensure the safety and efficacy of the products being packaged. Here are some materials commonly used for flexible packaging bags in the pharmaceutical and medical industries:

- Polyethylene (PE): PE is a commonly used material for pharmaceutical packaging due to its high moisture barrier properties. It can also be used for medical packaging applications, such as for blood bags.

- Polypropylene (PP): PP is often used for pharmaceutical packaging, as it is resistant to chemicals and has a high heat tolerance. It is also used for medical packaging, such as for syringe barrels.

- Polyethylene terephthalate (PET): PET is a common material used for pharmaceutical blister packaging due to its excellent barrier properties against moisture, oxygen, and light.

- Nylon: Nylon is used for medical packaging applications such as IV bags and catheter tubes due to its strength and durability.

- Aluminum foil: Aluminum foil is commonly used in pharmaceutical packaging, as it provides an excellent barrier to light, moisture, and oxygen. It is often used for blister packaging and sachets.

- Polyvinyl chloride (PVC): PVC is used for medical packaging applications such as IV bags and blood bags, as it is a clear and flexible material that can withstand extreme temperatures.

It's important to note that all materials used for pharmaceutical and medical packaging must comply with strict regulatory requirements to ensure the safety and efficacy of the products being packaged.

Which flexible packaging bag types are commonly used in Pharmaceutical & Medical industry?

There are several types of flexible packaging bags commonly used in the pharmaceutical and medical industry, including:

- Stand-up pouches: These are pouches that can stand upright on their own and are commonly used for packaging pills, capsules, and other small medical devices.

- Zipper bags: These are flexible bags with a zipper closure that allows for easy opening and closing. They are often used for packaging medical supplies and small devices.

- Barrier bags: These are bags made of specialized materials that provide a high barrier to moisture, oxygen, and other environmental factors. They are often used for packaging medical devices and equipment that require protection from moisture and other contaminants.

- Foil bags: These are bags made of aluminum foil or other metallized materials that provide a high barrier to moisture, light, and oxygen. They are often used for packaging pharmaceutical products that require protection from light and oxygen.

- Vacuum bags: These are bags that have had the air removed from them, creating a vacuum seal. They are often used for packaging medical devices and equipment that require protection from air and moisture.

Tamper-evident bags: These are bags that have a special seal that shows evidence of any attempt to open the bag. They are often used for packaging and transporting medications and other sensitive medical supplies.

Which functions are the most importance for pharmaceutical packaging bag?

Pharmaceutical packaging bags serve the critical role of preserving the quality and integrity of the medication they contain. The following functions are some of the most important for pharmaceutical packaging bags:

- Barrier Protection: Pharmaceutical packaging bags should provide a barrier to protect against moisture, light, oxygen, and other environmental factors that could potentially harm the medication.

- Durability: The packaging should be durable enough to withstand transport and handling without compromising the quality of the medication.

- Sterility: The packaging should be sterile to prevent contamination of the medication.

- Tamper-Evident: The packaging should be designed to provide evidence if it has been tampered with or opened.

- Compatibility: The packaging material should be compatible with the medication and not react with it to cause any chemical reactions or degradation.

- Ease of Use: The packaging should be easy to open, close, and dispense the medication.

- Informational: The packaging should provide clear and accurate information about the medication, such as dosage instructions, expiration date, and storage instructions.

Overall, pharmaceutical packaging bags must ensure the safety, efficacy, and stability of the medication they contain, as well as comply with regulatory requirements.